Custom Lipo Battery 801350 500mAh Li- Polymer Pouch Cell 803450 3.7V Lithium polymer Battery with PCB and Cable

Custom Lipo Battery 801350 500mAh Li- Polymer Pouch Cell 803450 3.7V Lithium polymer Battery with PCB and Cable

In the ever-evolving landscape of portable electronics, energy storage solutions play a pivotal role. Lithium Polymer (LiPo) batteries have emerged as a leading choice due to their high energy density, lightweight construction, and flexibility in design. This article delves into the specifics of two custom LiPo battery models: the 801350 500mAh Li-Polymer Pouch Cell and the 803450 3.7V Lithium Polymer Battery, both equipped with PCB (Printed Circuit Board) and cable recorder functionalities. We will explore their technical specifications, advantages, applications, safety considerations, and the impact of customization on modern electronic devices.

1. Introduction

The demand for efficient and reliable power sources in consumer electronics, medical devices, drones, wearables, and various IoT (Internet of Things) applications has surged in recent years. LiPo batteries, with their unique properties, have filled this gap, offering a balance between performance and form factor. The integration of PCBs and cables into these batteries further enhances their functionality, enabling better battery management, safety, and ease of integration into complex systems.

2. Understanding LiPo Batteries

2.1 Composition and Structure

LiPo batteries are constructed using a polymer electrolyte instead of the liquid electrolyte found in traditional lithium-ion batteries. This allows for a more flexible and lightweight design, often in the form of pouch cells. The electrodes, typically made of lithium cobalt oxide (LiCoO₂) for the cathode and graphite for the anode, are separated by a polymer separator. The entire assembly is encapsulated in a flexible aluminum-laminated pouch, providing protection and mechanical stability.

2.2 Advantages of LiPo Batteries

High Energy Density: LiPo batteries offer a higher energy density compared to other rechargeable battery technologies, allowing for longer runtimes in compact devices.

Lightweight and Flexible: The pouch cell design reduces weight and enables custom shapes and sizes, making them ideal for space-constrained applications.

Low Self-Discharge Rate: LiPo batteries have a relatively low self-discharge rate, preserving charge over extended periods of non-use.

High Discharge Rates: They can deliver high discharge currents, making them suitable for applications requiring bursts of power, such as drones and RC toys.

3. The 801350 500mAh Li-Polymer Pouch Cell

3.1 Technical Specifications

The 801350 500mAh Li-Polymer Pouch Cell is a compact and high-performance battery designed for applications where space and weight are critical factors.

Capacity: 500mAh

Nominal Voltage: 3.7V

Dimensions: The "801350" in the model number typically refers to the battery's dimensions in millimeters (8.0mm thickness × 13mm width × 50mm length), although this can vary slightly between manufacturers.

Charge/Discharge Rates: The battery supports standard charge and discharge rates, with specific maximum rates depending on the manufacturer's specifications.

Cycle Life: Typically offers 300-500 charge/discharge cycles, depending on usage patterns and depth of discharge.

3.2 Key Features

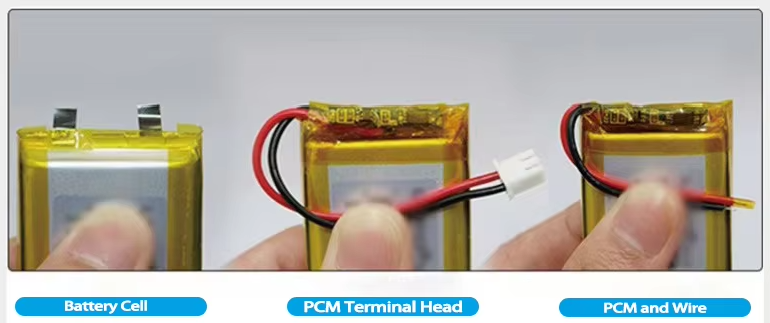

PCB Integration: The built-in PCB serves multiple functions, including overcharge protection, over-discharge protection, short-circuit protection, and sometimes temperature monitoring. This enhances battery safety and longevity.

Cable Recorder: The inclusion of a cable recorder simplifies the integration process, providing a standardized connection point for the battery to the device. It also allows for easier replacement and maintenance.

Customizable Form Factor: The pouch cell design enables customization of the battery's shape and size to fit specific device requirements, optimizing space utilization.

3.3 Applications

Wearable Devices: Smartwatches, fitness trackers, and other wearables benefit from the 801350's compact size and high energy density.

Medical Devices: Portable medical monitors, hearing aids, and other small medical electronics rely on the battery's reliability and safety features.

Remote Controls and Sensors: Compact remote controls, IoT sensors, and other low-power devices utilize the 801350 for extended runtimes.

4. The 803450 3.7V Lithium Polymer Battery

4.1 Technical Specifications

The 803450 3.7V Lithium Polymer Battery is another variant in the LiPo family, offering a slightly different form factor and capacity to suit diverse application needs.

Capacity: The capacity may vary depending on the specific variant, but a common capacity for this form factor is around 800mAh to 1000mAh. The "803450" likely indicates dimensions similar to 8.0mm thickness × 34mm width × 50mm length, with variations possible.

Nominal Voltage: 3.7V

Charge/Discharge Rates: Supports standard charge and discharge profiles, with specific maximum rates tailored to the battery's design.

Cycle Life: Offers a comparable cycle life to the 801350, with proper care and usage.

4.2 Key Features

Enhanced PCB Protection: In addition to basic protection features, the PCB in the 803450 may include advanced monitoring capabilities, such as state-of-charge (SoC) estimation and communication interfaces for battery management systems (BMS).

High-Quality Cables and Connectors: The cable recorder is designed for durability and reliability, with options for different connector types to match various device requirements.

Thermal Management: Some variants may include thermal sensors or heat dissipation features to ensure safe operation under high-load conditions.

4.3 Applications

Drones and UAVs: The 803450's higher capacity and discharge capabilities make it suitable for small to medium-sized drones, providing the necessary power for flight and onboard electronics.

Portable Audio Devices: Bluetooth speakers, headphones, and other portable audio products benefit from the battery's energy density and lightweight design.

Gaming Accessories: Wireless gaming controllers, VR headsets, and other gaming peripherals rely on the 803450 for long-lasting performance.

5. The Role of PCB and Cable Integration

5.1 PCB Functionality

The PCB integrated into both battery models serves as the brain of the battery management system. Its primary functions include:

Overcharge Protection: Prevents the battery from being charged beyond its safe voltage limit, which can cause thermal runaway and potential safety hazards.

Over-Discharge Protection: Stops the battery from discharging below a certain voltage, protecting the cells from irreversible damage.

Short-Circuit Protection: Detects and isolates short circuits, preventing excessive current flow that could damage the battery or the connected device.

Balancing (in Multi-Cell Configurations): For batteries composed of multiple cells, the PCB ensures that each cell is charged and discharged evenly, maintaining optimal performance and safety.

Communication and Monitoring: Advanced PCBs may include communication interfaces (e.g., I2C, SMBus) to relay battery status information to the host device, enabling intelligent power management.

5.2 Cable Recorder Benefits

The cable recorder simplifies the integration of the battery into the final product by providing a standardized connection point. Key advantages include:

Ease of Assembly: Reduces the complexity of wiring and connection during device manufacturing, saving time and costs.

Modularity: Allows for easy replacement of the battery without the need for soldering or complex disassembly, facilitating maintenance and upgrades.

Consistency: Ensures a reliable and consistent electrical connection, minimizing the risk of connection failures or intermittent power issues.

6. Safety Considerations

While LiPo batteries offer numerous advantages, they also require careful handling to ensure safety. Key safety considerations include:

Avoiding Physical Damage: Puncturing, crushing, or bending the battery can damage the internal structure, leading to leakage, overheating, or even explosion.

Proper Charging: Using a charger specifically designed for LiPo batteries and adhering to the recommended charge rates and voltage limits is crucial. Overcharging can be extremely dangerous.

Temperature Management: Avoid exposing the battery to extreme temperatures, both during charging and operation. High temperatures can accelerate aging and increase the risk of thermal runaway.

Storage Guidelines: When not in use, store LiPo batteries in a cool, dry place, preferably at around 50% charge, to maintain their health and safety.

Disposal and Recycling: LiPo batteries should be disposed of or recycled properly, as they contain hazardous materials. Many manufacturers and retailers offer recycling programs for used batteries.

7. Customization and Its Impact

The ability to customize LiPo batteries, such as the 801350 and 803450, has a significant impact on the electronics industry. Customization allows manufacturers to:

Optimize Form Factor: Tailor the battery's dimensions and shape to fit seamlessly into the device, maximizing internal space utilization.

Meet Specific Power Requirements: Adjust the battery's capacity, discharge rate, and other parameters to match the device's power demands, ensuring optimal performance and runtime.

Enhance Safety and Reliability: Incorporate additional safety features or monitoring capabilities into the PCB based on the application's requirements, reducing the risk of failures and improving user safety.

Differentiate Products: Unique battery designs can serve as a competitive advantage, allowing manufacturers to stand out in crowded markets with innovative and tailored solutions.

8. Future Trends in LiPo Battery Technology

As technology advances, several trends are shaping the future of LiPo batteries:

Higher Energy Densities: Research into new electrode materials and cell architectures aims to increase the energy density of LiPo batteries, enabling longer runtimes and smaller form factors.

Faster Charging: Developments in charging technologies, such as ultra-fast charging protocols and improved battery chemistry, promise to reduce charging times significantly.

Solid-State Electrolytes: The transition from polymer to solid-state electrolytes could enhance safety, increase energy density, and extend cycle life, marking a major leap forward in battery technology.

Integration with Renewable Energy: LiPo batteries are playing an increasingly important role in energy storage systems for renewable energy sources, such as solar and wind, enabling more efficient and reliable power distribution.

Sustainability and Recycling: With growing environmental concerns, there is a push towards more sustainable battery manufacturing processes and improved recycling methods to minimize the ecological footprint of LiPo batteries.

9. Conclusion

The 801350 500mAh Li-Polymer Pouch Cell and the 803450 3.7V Lithium Polymer Battery, equipped with PCB and cable recorder functionalities, represent the cutting edge of portable energy storage solutions. Their compact design, high energy density, and advanced safety features make them indispensable in a wide range of applications, from consumer electronics to industrial and medical devices. As technology continues to evolve, the customization and integration of LiPo batteries will play a pivotal role in driving innovation and meeting the ever-increasing demands of modern electronics. By understanding the technical specifications, advantages, and safety considerations of these batteries, manufacturers and designers can harness their full potential to create next-generation devices that are more efficient, reliable, and user-friendly.