Customized Lithium Polymer Batteries and Ultra-Thin Rechargeable Solutions--SER Battery

Customized Lithium Polymer Batteries and Ultra-Thin Rechargeable Solutions--SER Battery

In today's fast-paced world of technology, energy storage solutions have become paramount for numerous applications ranging from consumer electronics to aerospace systems. At the forefront of this revolution stands the customized Lithium Polymer (LiPo) battery, a technological marvel that offers unparalleled performance, safety, and flexibility. In this article, we delve into the intricacies of custom LiPo batteries, particularly the ultra-thin rechargeable polymer batteries, focusing on their design, applications, and the advantages they bring to the modern world.

I. Introduction to Lithium Polymer Batteries

Lithium Polymer batteries, commonly referred to as LiPo batteries, have revolutionized the battery industry by offering a lightweight, high-energy-density alternative to traditional battery chemistries. The key to their success lies in the use of a polymer electrolyte, which allows for a more flexible and compact design. This flexibility, in turn, enables manufacturers to create batteries that are tailored to specific applications, resulting in optimized performance and longer lifetimes.

II. The Benefits of Customized Lithium Polymer Batteries

Customized Lithium Polymer batteries offer a range of benefits that make them ideal for a wide variety of applications. First and foremost, their high energy density allows for more power to be packed into a smaller space, making them perfect for portable devices and other space-constrained applications. Additionally, the polymer electrolyte enables the batteries to be designed in various shapes and sizes, providing unparalleled flexibility in terms of integration and form factor.

Moreover, custom LiPo batteries offer improved safety compared to other lithium-based chemistries. The polymer electrolyte is less prone to thermal runaway, reducing the risk of fires or explosions. This makes them a safer choice for applications where safety is a top priority, such as in medical devices or aerospace systems.

III. Ultra-Thin Rechargeable Polymer Batteries

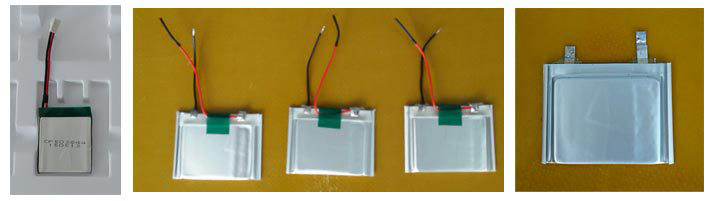

Within the realm of customized Lithium Polymer batteries, ultra-thin rechargeable polymer batteries stand out as a particularly innovative solution. These batteries are designed to be extremely thin, often measuring just a few millimeters in thickness. This ultra-thin profile enables them to be easily integrated into even the most compact devices, offering unprecedented portability and convenience.

The ultra-thin rechargeable polymer battery 15mAh 091525, for instance, is a testament to the capabilities of this technology. With a capacity of 15mAh and a unique identification code of 091525, this battery represents the pinnacle of energy storage in a minimalistic form factor. Its ultra-thin design makes it perfect for applications such as wearable devices, smart cards, and other ultra-compact electronics.

IV. Design and Manufacturing of Ultra-Thin Rechargeable Polymer Batteries

The design and manufacturing of ultra-thin rechargeable polymer batteries involve a sophisticated process that requires precision and expertise. The batteries are typically constructed using a multilayered structure, with the polymer electrolyte sandwiched between two electrode layers. The electrodes are typically made of lithium-based materials, such as Lithium Cobalt Oxide (LCO) or Lithium Iron Phosphate (LFP), which offer high energy density and good cycling performance.

The manufacturing process begins with the preparation of the electrode materials, which are then coated onto a thin metal foil. The polymer electrolyte is then applied in a precise layer between the electrodes, forming the battery cell. The cell is then sealed in a protective casing, ensuring safety and durability.

The key to achieving an ultra-thin profile lies in the precision and accuracy of the manufacturing process. Every layer of the battery must be carefully applied and controlled to ensure the desired thickness and performance. Additionally, the use of advanced materials and technologies, such as nanotechnology, further enhances the performance and reliability of the batteries.

V. Applications of Ultra-Thin Rechargeable Polymer Batteries

Ultra-thin rechargeable polymer batteries find applications in a wide range of industries and devices. In the consumer electronics sector, they are commonly used in wearable devices such as smartwatches, fitness trackers, and health monitoring devices. Their ultra-thin profile allows for comfortable and discreet integration into these devices, enhancing user experience and portability.

In addition, ultra-thin rechargeable polymer batteries are also finding their way into medical devices, where safety and reliability are paramount. These batteries are used in implantable medical devices, such as pacemakers and defibrillators, as well as in portable medical equipment, such as blood glucose monitors and inhalers. Their high energy density and safety features make them an ideal choice for these critical applications.

Moreover, the aerospace industry is also exploring the potential of ultra-thin rechargeable polymer batteries. In satellites and spacecraft, these batteries offer the perfect solution for providing reliable power in a compact and lightweight package.