high temperature Specialty Li-SOCL2 Batteries for the Oil & Gas Industry

Advancements in high temperature Specialty Li-SOCL2 Batteries for the Oil & Gas Industry: Meeting the Challenges of Deep-Well Exploration

In the realm of energy storage solutions, the oil and gas industry has witnessed a paradigm shift, driven primarily by the relentless pursuit of technological advancements in exploration and production techniques. As the depths of oil wells continue to push the boundaries of feasibility, the demand for reliable, high-performance, and specialized power sources has soared. Among these, Li-SOCL2 batteries, particularly those designed for extreme temperature conditions, have emerged as a pivotal technology, enabling the seamless operation of critical downhole instrumentation and tools. This article delves into the latest developments in high-temperature Li-SOCL2 batteries, their applications within the oil and gas sector, and the innovative strategies adopted by manufacturers like our company to cater to the industry's evolving needs.

Introduction

The oil and gas industry, a cornerstone of global energy supply, is constantly pushing the limits of technology to tap into previously inaccessible reserves. This quest has led to the proliferation of sophisticated electronic tools and instrumentation, such as electronic pressure gauges, wireless measurement-while-drilling (MWD) systems, and logging-while-drilling (LWD) tools, which require robust and reliable power sources capable of enduring the harsh environments encountered deep within the earth's crust.

Li-SOCL2 batteries, known for their high energy density, have gained significant traction in recent years as a potential solution for these demanding applications. However, traditional Li-SOCL2 batteries struggle to maintain their performance at elevated temperatures, a common challenge encountered in oil well environments. Consequently, the development of high-temperature Li-SOCL2 batteries has become a priority for manufacturers seeking to meet the industry's unique requirements.

High-Temperature LiSOCL2 Battery Technology

High-temperature LiSOCL2 batteries are designed to operate efficiently and safely in environments where conventional batteries falter, specifically in temperatures exceeding 100°C and up to 200°C. This adaptability is achieved through a combination of advanced materials science, electrolyte formulations, and innovative cell designs.

Materials Science

The success of high-temperature Li-socl2 batteries hinges on the selection of materials that can withstand extreme temperatures without compromising battery performance. The sulfur cathode, traditionally vulnerable to dissolution and polysulfide shuttling, is often modified with carbon-based additives or conductive polymers to enhance its stability and conductivity. Similarly, the lithium metal anode, prone to dendrite formation and instability at high temperatures, is being replaced or reinforced with alternative anode materials such as lithium-silicon alloys or lithium-coated graphite, offering improved cycling stability and safety.

Electrolyte Innovations

The electrolyte, the lifeblood of any battery, plays a crucial role in enabling high-temperature operation. Traditional organic electrolytes tend to degrade rapidly at elevated temperatures, leading to reduced battery life and potential safety hazards. Researchers have thus turned to solid-state electrolytes, ionic liquids, or specially formulated organic solvents that remain stable and conductive even at high temperatures. These electrolytes not only improve the battery's thermal stability but also contribute to enhanced safety by eliminating the risk of flammable liquid leaks.

Cell Design and Packaging

Cell design and packaging are equally important considerations for high-temperature Li-SOCL2 batteries. Advanced thermal management systems, including heat pipes, phase change materials, and active cooling mechanisms, are integrated into the battery packs to maintain optimal operating temperatures and prevent overheating. Additionally, the use of high-temperature-resistant materials for cell casings and insulation layers ensures the battery's structural integrity and safety under extreme conditions.

Applications in the Oil & Gas Industry

The oil and gas industry's reliance on sophisticated electronic equipment has created a significant market for high-performance, high-temperature batteries. Our company's range of high-temperature Li-SOCL2 batteries and battery packs, specifically designed for this sector, are finding widespread adoption in various applications:

Electronic Pressure Gauges

Downhole electronic pressure gauges are vital for monitoring and recording pressure data during drilling and production operations. These instruments require a reliable power source that can withstand the high temperatures and pressures encountered deep within oil wells. Our high-temperature Li-SOCL2 batteries, with their long shelf life and high energy density, provide the necessary power to ensure continuous and accurate pressure measurements.

Wireless Measurement-While-Drilling (MWD) Systems

MWD systems transmit real-time drilling parameters, including azimuth, inclination, and toolface orientation, to the surface, enabling drillers to make informed decisions and optimize drilling efficiency. These systems rely on wireless communication, which demands a robust and long-lasting power source. Our customized high-temperature Li-SOCL2 battery packs, offering voltages ranging from 18V to 36V, meet the unique power requirements of MWD systems, ensuring reliable communication and data transmission throughout the drilling process.

Logging-While-Drilling (LWD) Tools

LWD tools provide a wealth of geological information, including porosity, resistivity, and gamma ray data, crucial for evaluating the quality of hydrocarbon reserves. These tools operate in environments similar to MWD systems and, therefore, require similar power solutions. Our specialized high-temperature Li-SOCL2 battery packs, designed specifically for LWD applications, ensure continuous and accurate data acquisition, enhancing the overall success rate of drilling operations.

Customization and Specialization

The oil and gas industry's diverse range of applications necessitates a high degree of customization and specialization in battery design. Our company understands this need and offers a comprehensive suite of customization options to meet the unique requirements of our customers.

Non-Standard Battery Sizes

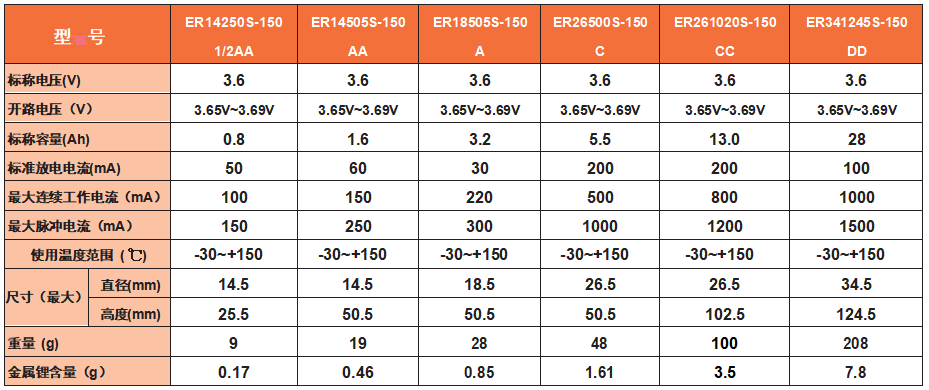

In addition to our standard battery sizes, we offer non-standard battery sizes such as ER13120S and ER33120S, tailored to fit specific equipment dimensions and power requirements. This flexibility allows customers to integrate our batteries seamlessly into their existing systems, minimizing modifications and maximizing compatibility.

Dedicated Plug-Ins and Battery Packs

We understand that each piece of equipment has its unique power needs and interfaces. Therefore, we offer dedicated plug-ins and battery packs, ensuring a seamless connection between the battery and the equipment. These custom solutions not only simplify installation but also enhance the overall reliability and performance of the system.

High-Voltage Battery Packs

For applications requiring higher voltages, we offer custom-built high-voltage battery packs, including 36V, 28.8V, 25.2V, and 18V options. These high temperature battery packs provide the necessary power to drive high-performance electronics and communication systems, ensuring reliable operation even in the most challenging environments.

Safety and Regulatory Compliance

In the oil and gas industry, safety is paramount. Our high-temperature Li-SOCL2 batteries are designed and manufactured to meet the strictest safety standards, including those set by regulatory bodies such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL). Rigorous testing protocols ensure that our batteries can withstand the harsh conditions encountered in oil wells without compromising on safety or performance.

Conclusion

As the oil and gas industry continues to push the boundaries of deep-well exploration, the demand for high-performance, high-temperature batteries will only grow. Our company, with its expertise in high-temperature Li-SOCL2 battery technology, is well-positioned to meet these challenges. By offering a wide range of standard and custom-built battery solutions, we enable our customers to operate their sophisticated electronic equipment reliably and efficiently, even in the most extreme environments. As the industry evolves, we remain committed to innovation and excellence, striving to deliver the most advanced power solutions for the oil and gas sector.