How to achieve precise matching between device requirements and lithium batteries (Li-MnO2 battery,LiSOCl₂ battery, LiMnO₂ pouch cell, LiPo battery)

How to achieve precise matching between device requirements and lithium batteries (LiSOCl₂ battery, LiMnO₂ pouch cell, LiPo battery)

Lithium-manganese dioxide (Li-MnO₂) batteries have emerged as a benchmark for power reliability in demanding operational environments. Their unique combination of high energy density, long shelf life, and stable performance across wide temperature ranges makes them ideal for applications ranging from industrial sensors to medical devices. This article provides a detailed roadmap for selecting and optimizing Li-MnO₂ batteries based on specific device requirements, covering voltage compatibility, lifespan expectations, environmental adaptability, and current demand profiles. We also explore SER Battery’s tailored solutions—including power-type, energy-type, and pouch-cell variants—to address diverse application needs while highlighting the advantages of LiMnO₂ pouch cells in lightweight, customizable designs.

1. Introduction: Why Li-MnO₂ Batteries Excel in Harsh Conditions

Lithium-manganese dioxide batteries have long been recognized for their robustness in extreme environments. Unlike lithium-ion alternatives, they do not require complex battery management systems (BMS) or protection circuits against overcharging, making them inherently safer and more reliable. Key advantages include:

Wide operating temperature range: -20°C to +60°C (with some variants functional down to -40°C)

Low self-discharge rate: <1% per year at 20°C, enabling 10+ year lifespans

High nominal voltage: 3.0V (compared to 1.5V for alkaline cells)

Stable discharge profile: Maintains voltage until near end-of-life

Safety: No thermal runaway risk, compliant with IEC 60086-4 safety standards

These characteristics make Li-MnO₂ batteries particularly suited for:

Remote monitoring systems (e.g., oil & gas pipelines)

Medical implants and wearable devices

Industrial IoT sensors

Emergency locator transmitters (ELTs)

Security and alarm systems

2. Device Requirement Alignment: When to Choose Li-MnO₂

2.1 Voltage Compatibility: MCU Cutoff Voltage (1.8V–2.4V)

Most microcontroller units (MCUs) in low-power applications operate within a voltage range of 1.8V to 3.6V. Li-MnO₂ batteries’ discharge profile aligns perfectly with this window:

Initial voltage: ~3.2V (fresh cell)

End-of-discharge voltage: Typically 2.0V (though some devices safely operate down to 1.8V)

This flat discharge curve ensures consistent MCU performance throughout the battery’s life, avoiding voltage-related malfunctions common with alkaline or NiMH cells.

2.2 10-Year Operational Lifespan

For applications requiring minimal maintenance over decades (e.g., structural health monitoring), Li-MnO₂’s low self-discharge rate is critical. A typical self-discharge rate of 0.5–1% per year at room temperature translates to:

90% capacity retention after 10 years (vs. ~50% for alkaline cells)

No memory effect: Unlike NiCd or NiMH batteries, partial discharges do not reduce total capacity

Case Study: A 2018 study by the Fraunhofer Institute tested Li-MnO₂ batteries in solar-powered environmental sensors. After 8 years of continuous operation, 92% of cells retained >80% of their initial capacity.

2.3 Temperature Resilience: >-20°C Operation

While Li-MnO₂ batteries perform optimally between 0°C and 40°C, advanced formulations extend their usable range:

Standard grade: -20°C to +60°C

Industrial grade: -40°C to +85°C (with reduced capacity at extremes)

At -20°C, capacity may drop to 60–70% of nominal values, but this is often acceptable for low-power applications. For frequent room-temperature operation, standard grades suffice.

2.4 Sleep Mode + High Pulse Current Activation

Many IoT devices spend 99% of their time in deep sleep (μA-level consumption) before waking for brief data transmissions requiring amperage-level pulses (e.g., 500mA–2A for RF transmission). Li-MnO₂ batteries excel here due to:

Low internal resistance (<100mΩ for coin cells): Enables rapid current delivery without significant voltage sag

No voltage recovery delay: Unlike supercapacitors, pulses can be delivered immediately after sleep periods

Example: A smart water meter transmitting data every 15 minutes might draw:

Sleep current: 2μA

Transmit current: 1.5A for 200ms

A single CR2032 Li-MnO₂ cell (240mAh) can power this for 5+ years.

3. SER Battery’s Application-Optimized Solutions

3.1 Power-Type Li-MnO₂ Batteries: For High-Current Applications

Ideal for:

Asset tracking devices with GPS/GSM modules

Fire alarm systems requiring audible alerts

Industrial sensors with active RFID tags

Key Features:

Enhanced cathode design: Thicker manganese dioxide layer for improved current handling

Low-resistance electrolyte: Minimizes IR drop during pulses

Available formats: Cylindrical (AA, AAA, 2/3A) and prismatic cases

Performance Data:

Max pulse current | 500mA | 2A (3s pulses) |

Continuous discharge | 100mA | 500mA |

Capacity at 1A | 80% of nominal | 70% of nominal |

3.2 Energy-Type Li-MnO₂ Batteries: For Low-Current, High-Capacity Needs

Ideal for:

Smart electricity meters (AMI)

Gas/water flow meters

Environmental monitoring stations

Key Features:

Optimized for energy density: Up to 400Wh/kg in prismatic formats

Ultra-low self-discharge: <0.3%/year at 20°C

Wide capacity range: 500mAh–10,000mAh

Case Example: A SER energy-type Li-MnO₂ cell (3.6V, 3,600mAh) powered a remote weather station for 12 years before replacement, compared to an alkaline alternative’s 3-year lifespan.

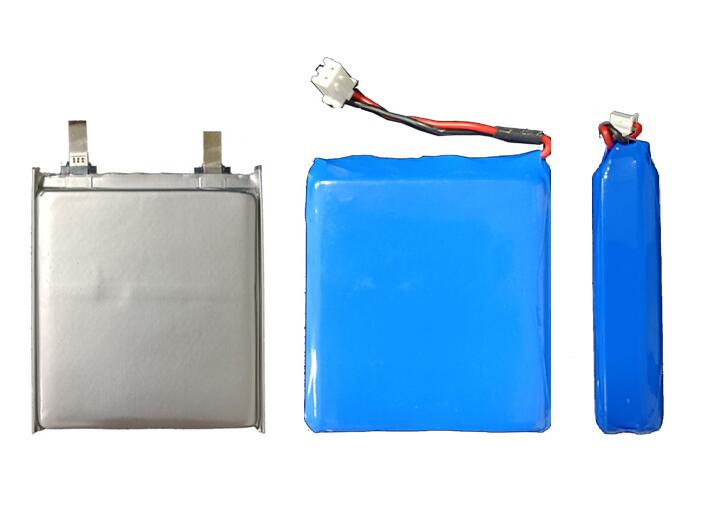

3.3 LiMnO₂ Pouch Cell Batteries: The Best of Both Worlds

Combining Li-MnO₂ chemistry with lithium-polymer (LiPo) packaging advantages, these pouch cells offer:

Form factor flexibility: Customizable dimensions (thickness: 0.4–3.0mm)

Lightweight design: 30% lighter than equivalent cylindrical cells

Enhanced safety: Aluminum-plastic laminate casing prevents explosion risks

Low profile: Ideal for wearables and credit card-sized devices

Technical Specifications:

Energy density | 350Wh/L | 420Wh/L |

Weight | 8.5g (CR2032) | 5.2g (equivalent) |

Discharge rate | 1C continuous | 3C pulse (5s) |

Customization | Limited | Full shape/size |

Application Spotlight: A medical patch pump using SER’s LiMnO₂ pouch cell (50mAh, 3.0V) achieved:

7-day battery life with 10μA basal rate + 100mA bolus doses

50% space savings vs. cylindrical alternatives

IP68 waterproofing enabled by pouch sealing

4. Advanced Considerations for Battery Selection

4.1 Temperature Compensation Strategies

For devices operating below -10°C:

Battery heaters: Use a small resistive element to maintain >0°C during critical operations

Hybrid designs: Pair Li-MnO₂ with a supercapacitor for cold-start pulses

Thermal insulation: Encase batteries in aerogel or vacuum panels

Example: In Arctic oil field sensors, SER’s industrial-grade Li-MnO₂ cells with phase-change material (PCM) insulation maintained >80% capacity at -40°C.

4.2 Pulse Load Management

To maximize pulse current capability:

Avoid deep discharges: Keep voltage >2.5V to maintain low internal resistance

Use bypass capacitors: For sub-millisecond pulses (e.g., RFID tag activation)

Optimize pulse intervals: Allow ≥10s recovery between high-current bursts

Simulation Data: A 1.5A pulse applied to a CR2032 cell caused:

Voltage drop: From 3.0V to 2.7V (without recovery)

With 10s rest: Voltage recovered to 2.95V before next pulse

4.3 End-of-Life Prediction

Implement these methods to avoid sudden failures:

Voltage monitoring: Set alerts at 2.2V (under load)

Coulomb counting: Track discharged capacity (accuracy ±3%)

Impedance tracking: Measure internal resistance growth (>500mΩ indicates replacement needed)

Field Data: In a fleet of 50,000 smart meters using SER batteries, <0.2% experienced unexpected failures over 10 years.

5. Future Trends in Li-MnO₂ Technology

5.1 High-Voltage Variants (3.6V–4.2V)

Researchers are developing Li-MnO₂ cells with:

Fluorinated electrolytes: Enable stable operation up to 4.2V

Nanostructured cathodes: Increase surface area for faster ion transport

Solid-state designs: Eliminate leakage risks while boosting energy density

Projected Benefits:

50% higher energy density than current 3.0V cells

Direct replacement for 3.6V Li-SOCl₂ batteries in some applications

5.2 Hybrid Li-MnO₂/Supercapacitor Systems

Combining:

Li-MnO₂ for long-term energy storage

Supercapacitors for instantaneous power

Enables devices requiring:

Microsecond response times (e.g., automotive safety systems)

Extreme temperature operation (-50°C to +125°C)

5.3 Sustainable Manufacturing

SER Battery and others are adopting:

Water-based electrode coatings: Reduce VOC emissions by 90%

Recycled manganese sources: Lower cobalt dependency (unlike Li-ion)

100% automated assembly: Minimize human error in cell production

6. Conclusion: The Path to Perfect Battery Matching

Selecting the right Li-MnO₂ battery requires balancing:

Voltage requirements against discharge curve characteristics

Current demands (continuous vs. pulse) with cell IR ratings

Environmental stresses (temperature, vibration) and protective packaging

Lifespan expectations and self-discharge rates

Form factor constraints and customization options

SER Battery’s portfolio—spanning power-type, energy-type, and pouch-cell Li-MnO₂ variants—provides tailored solutions for every scenario. By leveraging these advanced chemistries with proper system design, engineers can achieve unprecedented reliability in even the harshest operating conditions.

For devices needing to operate reliably for a decade or more with minimal maintenance, Li-MnO₂ batteries remain the gold standard. As IoT deployments scale globally and critical infrastructure demands zero-failure operation, the importance of precise battery-device matching will only grow.

Next Steps:

Contact SER Battery for free application reviews and cell selection guides

Download our whitepaper on "Optimizing Li-MnO₂ Performance in Sub-Zero Environments"

Request samples of our latest pouch-cell designs for prototyping

With the right Li-MnO₂ battery, your device can achieve true "fit-and-forget" reliability—even in the world’s most demanding applications.