Differences Between Lithium-Ion Batteries and Lithium-Polymer Batteries, and the Advantages of Pouch Batteries

Differences Between Lithium-Ion Batteries and Lithium-Polymer Batteries, and the Advantages of Pouch Batteries

In the realm of consumer electronics, batteries play a crucial role in determining the performance, portability, and overall user experience. Among the various types of batteries available, lithium-ion batteries (LIBs) and lithium-polymer batteries (LIPO battery) are two of the most prominent. Additionally, pouch batteries, a specific type of lithium-polymer battery, offer unique advantages that make them suitable for a wide range of applications. This article delves into the differences between lithium-ion and lithium-polymer batteries and highlights the advantages of pouch batteries.

Differences Between Lithium-Ion Batteries and Lithium-Polymer Batteries

Structural Characteristics

Lithium-ion batteries and lithium-polymer batteries differ primarily in their structural characteristics, particularly in the electrolyte used within the battery. Lithium-ion batteries utilize a liquid electrolyte, which requires a sturdy casing to prevent leakage. On the other hand, lithium-polymer batteries use a solid or gel-like polymer electrolyte, which eliminates the need for a rigid casing and allows for greater flexibility in design.

The solid electrolyte in lithium-polymer batteries is often semi-colloidal, providing a stable environment for the lithium ions to move between the anode and cathode during charging and discharging. This solid-state electrolyte also contributes to the overall safety of the battery, as it reduces the risk of leakage and short-circuiting.

Appearance and Shape

The appearance and shape of lithium-ion and lithium-polymer batteries also differ significantly. Lithium-ion batteries are commonly found in cylindrical or prismatic shapes, such as the popular 18650 cylindrical battery used in many portable power banks. These batteries are rigid and have a fixed form factor.

In contrast, lithium-polymer batteries can be manufactured in various shapes and sizes, often in a flat, rectangular, or pouch-like form. This flexibility in design allows lithium-polymer batteries to be tailored to fit the specific needs of electronic devices, making them ideal for use in smartphones, tablets, and other portable electronics where space is a constraint.

Energy Density and Thickness

Another key difference between lithium-ion and lithium-polymer batteries is their energy density and thickness. Lithium-polymer batteries, due to their solid electrolyte and flexible design, can achieve higher energy densities and thinner profiles than lithium-ion batteries of the same volume.

The minimum thickness of lithium-polymer batteries can reach 0.5mm, making them ultra-thin and lightweight. This thinness, combined with their high energy density, allows lithium-polymer batteries to store more energy in a smaller space, which is particularly beneficial for electronic devices that require long battery life and compact designs.

Safety Performance

Safety is a critical consideration in battery technology. Lithium-ion batteries, with their liquid electrolyte, can pose safety risks if not properly managed. Overcharging, short-circuiting, or exposure to high temperatures can lead to thermal runaway and potential explosion.

Lithium-polymer batteries, on the other hand, offer improved safety performance due to their solid electrolyte and flexible packaging. In the event of overcharging, short-circuiting, or internal malfunctions, lithium-polymer batteries are more likely to swell or puff up rather than explode. This swelling serves as a visible warning of potential issues and allows for safer handling and disposal.

Advantages of Pouch Batteries

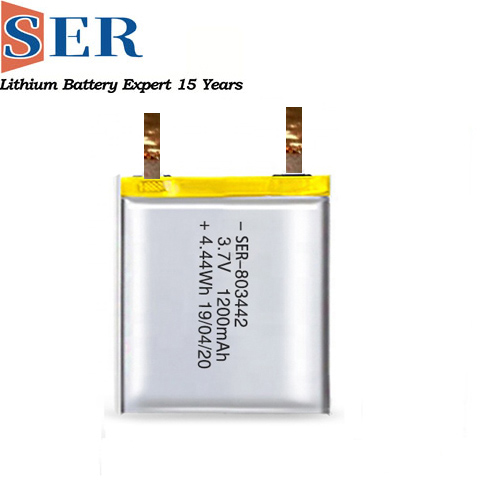

Pouch batteries, also known as ultra thin battery, lithium-polymer batteries or aluminum-plastic film batteries, are a specific type of battery packaging that offers a range of advantages. These advantages make pouch batteries suitable for various applications, particularly in consumer electronics where performance, safety, and design flexibility are paramount.

High Energy Density

Pouch batteries provide high energy density, meaning they can store more energy in the same volume compared to other types of batteries. This high energy density is achieved through the use of a solid or gel-like polymer electrolyte, which allows for a more compact battery design.

For electronic devices that prioritize long battery life and compact form factors, such as smartphones and tablets, pouch batteries offer a significant advantage. They enable these devices to operate for longer periods without needing to be recharged, while still maintaining a sleek and lightweight design.

Design Flexibility

The flexible packaging of pouch batteries allows for greater design freedom. Unlike rigid lithium-ion batteries, pouch batteries can be customized to fit the specific dimensions and shape requirements of electronic devices.

This design flexibility is particularly beneficial for product designers who need to optimize battery placement within a device to maximize space efficiency and minimize weight. Pouch batteries can be tailored to fit irregular shapes and tight spaces, enabling the creation of innovative and aesthetically pleasing designs.

Lightweight

The use of aluminum-plastic film as the outer packaging material for pouch batteries contributes to their lightweight nature. Compared to hard-cased lithium-ion batteries, pouch batteries weigh less, which is crucial for portable electronic devices.

Lightweight batteries reduce the overall weight of the device, making it more comfortable to carry and use. This is particularly important for devices like smartphones and tablets, where every gram counts in terms of user experience and portability.

Low Internal Resistance

Pouch batteries have a lower internal resistance than some other types of batteries, which helps to reduce energy loss and improve thermal efficiency. A lower internal resistance allows for more efficient energy transfer during charging and discharging, resulting in longer battery life and better performance.

Additionally, pouch batteries can support higher discharge currents, making them suitable for applications that require high power output. This makes them ideal for devices like electric vehicles, drones, and other high-performance electronics.

Safety

As mentioned earlier, pouch batteries offer improved safety performance compared to lithium-ion batteries. The solid electrolyte and flexible packaging of pouch batteries reduce the risk of leakage, short-circuiting, and thermal runaway.

In the event of overcharging, short-circuiting, or internal malfunctions, pouch batteries are more likely to swell or puff up rather than explode. This visible warning allows for safer handling and disposal, reducing the potential for harm to users and the environment.

Low-Temperature Performance

Pouch batteries tend to perform better in low-temperature conditions than some other types of batteries. The flexible packaging and solid electrolyte of pouch batteries allow them to maintain their performance even in cold environments, making them suitable for use in outdoor electronics and other devices that may be exposed to extreme temperatures.

Cost-Effectiveness

With advancements in manufacturing technology and the increasing scale of production, the cost of pouch batteries is gradually decreasing. This cost-effectiveness makes pouch batteries a more viable option for large-scale applications, such as in electric vehicles and energy storage systems.

As the demand for pouch batteries grows, manufacturers are investing in research and development to further reduce costs and improve performance. This ongoing innovation will likely lead to even greater adoption of pouch batteries in various industries.

Disadvantages of Pouch Batteries

While pouch batteries offer numerous advantages, they also have some disadvantages that need to be considered.

Low Mechanical Strength

The aluminum-plastic film packaging of pouch batteries has a lower mechanical strength compared to the metal casing of lithium-ion batteries. This makes pouch batteries more susceptible to physical damage, such as punctures or tears, which can compromise their performance and safety.

To mitigate this risk, pouch batteries are often encased in additional protective layers or housings to provide extra durability and protection.

Poor Pressure Resistance

Pouch batteries can deform under external pressure, which may damage the internal structure and affect battery performance. This is particularly problematic in applications where the battery may be subjected to mechanical stress, such as in electric vehicles or portable devices that are frequently dropped or handled roughly.

To address this issue, manufacturers often design pouch batteries with reinforced packaging or additional structural support to improve their pressure resistance.

Heat Dissipation

The aluminum-plastic film packaging of pouch batteries has a lower thermal conductivity than metal casings, which can limit their heat dissipation capabilities. This can lead to higher temperatures during charging and discharging, potentially reducing battery life and performance.

To improve heat dissipation, manufacturers may incorporate additional cooling mechanisms or use materials with higher thermal conductivity in the packaging of pouch batteries.

Cost

Although the cost of pouch batteries is decreasing, they still tend to be more expensive than some traditional cylindrical or prismatic lithium-ion batteries. This higher cost can be a barrier to adoption, particularly in cost-sensitive applications.

However, as manufacturing technologies improve and production scales increase, the cost of pouch batteries is expected to continue to decline, making them more competitive in the market.

Packaging Reliability

The packaging reliability of pouch batteries is generally lower than that of lithium-ion batteries with metal casings. This can affect the battery's lifespan and performance, particularly in applications where the battery is subjected to frequent charging and discharging cycles or extreme environmental conditions.

To improve packaging reliability, manufacturers often use advanced sealing techniques and materials to ensure that the pouch battery remains intact and performs as expected over its lifetime.

Module Efficiency

When assembling battery modules, pouch batteries tend to have lower module efficiency compared to lithium-ion batteries. This is because more structural components are required to fix and connect the pouch batteries, which increases the overall weight and volume of the battery system.

To improve module efficiency, manufacturers are developing innovative packaging and assembly techniques that minimize the use of structural components and optimize the arrangement of pouch batteries within the module.

Environmental Adaptability

Pouch batteries have relatively weak environmental adaptability. For example, in high-humidity environments, the aluminum-plastic film packaging can absorb moisture, which may affect battery performance and lifespan.