Lithium Polymer Batteries: Revolutionizing Portable Power Solutions

Lithium Polymer Batteries: Revolutionizing Portable Power Solutions

Introduction

In the ever-evolving landscape of energy storage technology, lithium polymer (LiPo) batteries have emerged as a game-changer, particularly in applications where energy density, weight efficiency, and reliability are paramount. First gaining prominence in the early 2000s with mobile devices, LiPo batteries have since become ubiquitous across industries ranging from consumer electronics to aerospace. This article delves into the technical nuances, advantages, and diverse applications of LiPo batteries, highlighting their role as a leader in modern energy solutions.

Technical Overview: How LiPo Batteries Work

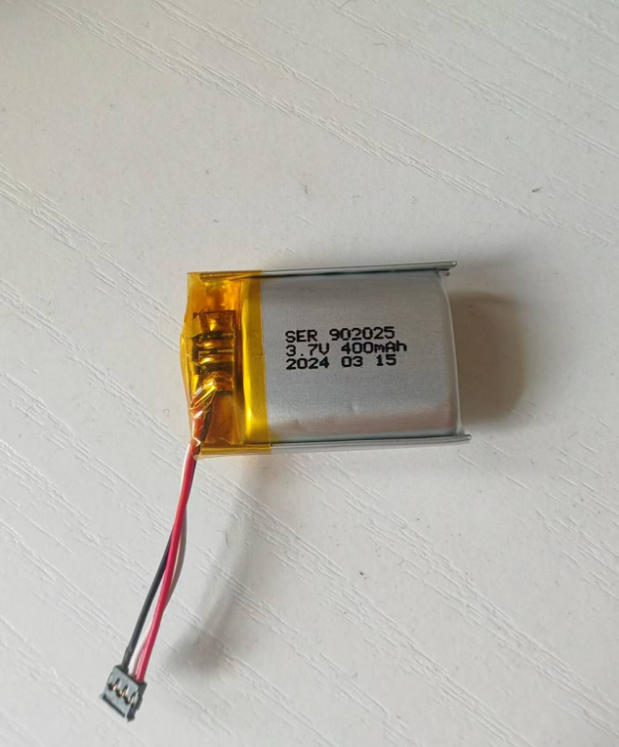

LiPo batteries belong to the lithium-ion family, sharing the same fundamental electrochemical principles but differing significantly in construction and performance. A standard LiPo cell operates at a nominal voltage of 3.7V, with capacities spanning from 35mAh to 2800mAh. Their core consists of lithium cobalt oxide (LiCoO₂) cathodes and graphite anodes, separated by a polymer electrolyte—a key differentiator from conventional lithium-ion batteries that use liquid electrolytes. This polymer separator enables flexible, lightweight packaging, often in pouch-style formats, which reduces weight by up to 20% compared to cylindrical cells.

The energy density of LiPo batteries, measured in watt-hours per kilogram (Wh/kg), surpasses that of nickel-metal hydride (NiMH) and lead-acid batteries by a substantial margin. For instance, a typical LiPo battery offers around 150–250 Wh/kg, while NiMH batteries provide roughly 60–120 Wh/kg. This advantage stems from lithium’s high electrochemical potential and the polymer electrolyte’s ability to facilitate efficient ion transport. Additionally, LiPo batteries exhibit low self-discharge rates (约5% per month vs. 20–30% for NiMH), making them ideal for devices requiring long-term storage without frequent recharging.

Design Advantages: Lightweight and Compact

One of LiPo batteries’ most significant strengths lies in their weight-to-energy ratio. The polymer electrolyte and flexible pouch design eliminate the need for rigid metal casings, reducing overall weight by up to 20% compared to cylindrical lithium-ion cells. This lightweight construction is critical in industries where every gram matters, such as drones, wearables, and medical devices. For example, a drone equipped with LiPo batteries can achieve longer flight times and greater maneuverability due to reduced payload.

The thin-profile pouch cells, ranging from 1mm to 10mm in thickness, also enable innovative form factors. Engineers can integrate these batteries into curved or irregularly shaped devices, such as smartwatches or flexible displays, where traditional cylindrical cells would be impractical. This design flexibility has driven the adoption of LiPo batteries in cutting-edge technologies like foldable smartphones and implantable medical devices.

Safety Innovations: Protecting Against Critical Failures

Despite their numerous advantages, LiPo batteries are not without challenges. Their sensitive chemistry and susceptibility to thermal runaway have necessitated robust safety measures. Modern LiPo batteries incorporate multi-layer protection circuits, including:

Overcharge Protection: Prevents cell voltages from exceeding 4.2V, mitigating the risk of lithium plating and electrolyte decomposition.

Overdischarge Protection: Halts discharge at 2.5–3.0V to avoid copper dissolution from the anode current collector.

Short-Circuit Protection: Disconnects the battery in case of accidental shorts, preventing excessive current flow.

Temperature Monitoring: Some advanced models include thermistors to monitor internal temperatures and adjust charging rates dynamically.

Furthermore, advancements in separator materials and electrode coatings have enhanced thermal stability. For instance, ceramic-coated separators can withstand higher temperatures before melting, buying critical time for safety mechanisms to engage.

Applications Across Industries

The versatility of LiPo batteries has led to their adoption across diverse sectors:

Consumer Electronics:

Smartphones and Laptops: LiPo’s high energy density enables sleek designs without compromising battery life.

Wearables: From fitness trackers to augmented reality (AR) glasses, LiPo batteries power devices that demand compact, lightweight solutions.

Drones and Robotics:

The combination of high discharge rates and low weight makes LiPo batteries ideal for unmanned aerial vehicles (UAVs). A 6S LiPo (22.2V) configuration, for example, can deliver instantaneous currents exceeding 100A, enabling rapid acceleration and agile flight.

Medical Devices:

Portable glucose monitors and implantable pacemakers benefit from LiPo’s long cycle life and low self-discharge.

Automotive:

While electric vehicles (EVs) primarily use lithium-ion prismatic cells, LiPo batteries are finding niche applications in lightweight EVs and e-bikes, where their flexibility and energy density offer design advantages.

Aerospace:

Satellites and cubesats utilize LiPo batteries for their high specific energy and radiation tolerance in low-Earth orbit.

Manufacturing Excellence: Preventing Common Issues

The production process of LiPo batteries is meticulously controlled to address common drawbacks associated with lithium-ion technology. For instance:

Swelling Prevention: Rigorous moisture control during electrolyte injection and sealing processes minimizes gas generation, reducing the risk of pouch swelling.

Cycle Life Optimization: Advanced electrode formulations and precision assembly techniques enhance longevity, with some LiPo cells retaining 80% capacity after 500 cycles.

Quality Control: Automated optical inspection and impedance testing ensure consistent performance across batches.

Environmental Considerations and Sustainability

While LiPo batteries offer superior performance, their environmental impact warrants attention. The cobalt in LiCoO₂ cathodes raises ethical sourcing concerns, and improper disposal can lead to soil contamination. However, ongoing research is exploring alternatives like lithium iron phosphate (LFP) cathodes, which use more abundant materials. Additionally, recycling technologies are emerging to recover lithium, cobalt, and nickel from spent batteries, promoting a circular economy.

Future Trends: Innovations on the Horizon

The LiPo battery market continues to evolve with several promising developments:

Solid-State Batteries: Replacing liquid electrolytes with solid polymers could further enhance safety and energy density.

Silicon Anodes: The integration of silicon-based anodes may boost capacity by 40–50% compared to graphite.

Fast-Charging Technologies: Advances in electrode architecture and electrolyte additives are enabling charging times under 10 minutes.

Flexible and Stretchable Batteries: LiPo’s inherent flexibility makes it a candidate for wearable devices requiring conformal power sources.

Conclusion

Lithium polymer batteries have transcended their niche origins to become a cornerstone of modern energy storage. Their unparalleled energy density, lightweight design, and robust safety features position them as the optimal choice for applications where performance and portability are non-negotiable. As industries push the boundaries of miniaturization and efficiency, LiPo batteries will remain at the forefront, powering innovation from consumer gadgets to cutting-edge aerospace technology. With ongoing advancements in materials science and manufacturing, the future of LiPo batteries promises even greater energy solutions for a sustainable, technology-driven world.