Non-rechargeable super slim battery and rechargeable super slim lipo battery

Non-rechargeable super slim battery and rechargeable super slim lipo battery

Abstract

The quest for ever-smaller and more efficient electronic devices has driven the development of super slim batteries, which offer a compact and lightweight power solution without compromising on performance. This article explores the world of super slim batteries, focusing on LiMnO2 super slim battery, non-rechargeable,super slim LiPo battery(super slim Lithium Polymer battery), and general lithium variants. We will delve into their characteristics, manufacturing processes, advantages, challenges, and the diverse range of applications they enable. By understanding these aspects, we can appreciate the pivotal role super slim batteries play in advancing modern technology.

1. Introduction

In an era where technology is constantly evolving towards miniaturization and portability, the need for super slim batteries has become paramount. These batteries are designed to fit into the tightest of spaces while still providing sufficient energy to power a wide array of electronic devices. From smartwatches and fitness trackers to medical implants and smart cards, super slim batteries are the unsung heroes that keep these devices running smoothly.

The development of super slim batteries has been made possible through advancements in materials science, battery chemistry, and manufacturing techniques. By optimizing the design and composition of these batteries, manufacturers have been able to achieve remarkable thinness without sacrificing energy density or safety.

2. Types of Super Slim Batteries

2.1 Super Slim LiMnO₂ Batteries

Lithium Manganese Dioxide (LiMnO₂) batteries are a popular choice for super slim applications due to their high energy density, stable voltage output, and relatively low cost. These batteries are typically non-rechargeable, making them ideal for devices that require a long shelf life and a reliable power source over an extended period.

2.1.1 Characteristics

High Energy Density: LiMnO₂ batteries offer a high energy-to-volume ratio, allowing them to store a significant amount of energy in a very thin form factor. This makes them suitable for applications where space is at a premium, such as in smart cards and RFID tags.

Stable Voltage Output: The voltage output of LiMnO₂ batteries remains relatively constant over a wide range of discharge conditions, ensuring consistent performance of the connected electronic devices. This stability is crucial for devices that require precise power regulation, like medical sensors.

Long Shelf Life: These batteries have a long self-discharge rate, meaning they can retain their charge for extended periods when not in use. This makes them ideal for applications where the battery may be stored for months or even years before being activated, such as in emergency backup power sources.

Safety: LiMnO₂ batteries are generally considered to be safe, with a low risk of thermal runaway or explosion. This is due to their stable chemistry and the use of non-flammable electrolytes in some cases.

2.1.2 Manufacturing Process

The manufacturing process of super slim LiMnO₂ batteries involves several steps. First, the cathode material, which is lithium manganese dioxide, is mixed with a binder and a conductive additive to form a slurry. This slurry is then coated onto a thin metal foil substrate, typically aluminum, to create the cathode electrode. The anode is usually made of lithium metal, which is deposited onto a copper foil substrate.

Next, a separator membrane, which is a thin, porous material that prevents direct contact between the cathode and anode while allowing the flow of lithium ions, is placed between the two electrodes. The electrodes and separator are then laminated together to form a multi-layer structure.

An electrolyte solution, which is typically a lithium salt dissolved in an organic solvent, is injected into the battery cell to facilitate the movement of lithium ions during charging and discharging. Finally, the battery cell is sealed in a thin, flexible package, often using a laminated film material, to protect it from moisture and mechanical damage.

2.1.3 Applications

Super slim LiMnO₂ batteries find applications in a variety of fields, including:

Smart Cards: Used in credit cards, debit cards, and identification cards to power the embedded electronic components, such as chips and antennas. Their long shelf life and stable voltage output make them ideal for this application.

RFID Tags: Provide power for radio frequency identification tags used in inventory management, access control, and asset tracking systems. The thin form factor of these batteries allows them to be easily integrated into the small tags.

Medical Devices: Power miniature medical devices, such as implantable sensors, drug delivery systems, and hearing aids. The high energy density and safety of LiMnO₂ batteries are crucial for these life-saving applications.

Backup Power Sources: Can be used as emergency backup power sources for devices like real-time clocks, memory chips, and other low-power electronics that need to retain data or function during power outages.

2.2 Non-Rechargeable Super Slim Batteries

Non-rechargeable super slim batteries encompass a range of chemistries, including LiMnO₂ as discussed above, as well as other primary battery types like alkaline and silver oxide batteries. These batteries are designed for single-use applications and offer several advantages in terms of simplicity, cost, and reliability.

2.2.1 Characteristics

Simplicity: Non-rechargeable batteries do not require complex charging circuits or management systems, making them easier to integrate into electronic devices. This simplicity also reduces the overall cost of the device.

Cost-Effectiveness: Due to their simple design and the use of readily available materials, non-rechargeable super slim batteries are often more cost-effective than their rechargeable counterparts, especially for high-volume applications.

Reliability: These batteries have a well-established performance history and are known for their reliability. They provide a consistent power output over their lifetime and are less prone to issues such as overcharging or memory effect.

Long Shelf Life: Similar to LiMnO₂ batteries, non-rechargeable super slim batteries generally have a long shelf life, making them suitable for applications where the battery may be stored for extended periods before use.

2.2.2 Applications

Non-rechargeable super slim batteries are widely used in various consumer and industrial applications, such as:

Consumer Electronics: Power remote controls, calculators, toys, and other small electronic devices that have low power requirements and do not need to be recharged frequently.

Industrial Sensors: Provide power for industrial sensors used in monitoring systems, such as temperature sensors, pressure sensors, and humidity sensors. These sensors are often located in remote or hard-to-reach areas, making non-rechargeable batteries a convenient power source.

Military and Aerospace: Used in military equipment, such as night vision goggles, communication devices, and guidance systems, as well as in aerospace applications like satellites and spacecraft. The reliability and long shelf life of non-rechargeable batteries are crucial for these critical applications.

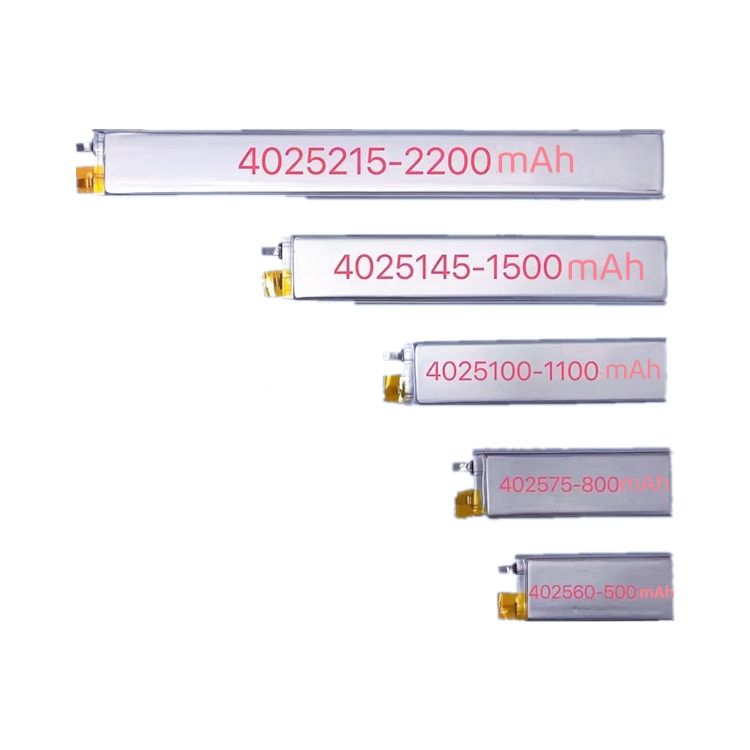

2.3 Super Slim LiPo Batteries

Lithium Polymer (LiPo) batteries are a type of rechargeable battery that has gained popularity in super slim applications due to their high energy density, flexibility in shape and size, and good discharge characteristics. Unlike traditional lithium-ion batteries, which use a liquid electrolyte, LiPo batteries use a solid or gel-like polymer electrolyte, allowing for the fabrication of thin, flexible battery cells.

2.3.1 Characteristics

High Energy Density: LiPo batteries offer a high energy density, similar to that of lithium-ion batteries, making them suitable for applications that require a long battery life in a compact form factor.

Flexibility: The polymer electrolyte used in LiPo batteries allows for the fabrication of battery cells in a variety of shapes and sizes, including super slim profiles. This flexibility enables designers to create devices with unique form factors and curved surfaces.

Good Discharge Characteristics: LiPo batteries have a relatively flat discharge voltage curve, providing consistent power output over a wide range of discharge conditions. This is important for devices that require a stable power supply, such as cameras and portable audio players.

Rechargeable: Being rechargeable, LiPo batteries can be used multiple times, reducing the need for frequent battery replacements and making them more environmentally friendly.

2.3.2 Manufacturing Process

The manufacturing process of super slim LiPo batteries is similar to that of traditional LiPo batteries but with additional steps to achieve the thin form factor. The process involves the preparation of the cathode and anode materials, the fabrication of the electrodes, the assembly of the battery cell, and the encapsulation of the battery.

The cathode and anode materials are typically prepared by coating a slurry of the active material, binder, and conductive additive onto a thin metal foil substrate. The electrodes are then dried, calendared, and cut to the desired size and shape. The battery cell is assembled by laminating the cathode, anode, and a separator membrane together, and then injecting a polymer electrolyte.

To achieve a super slim profile, the thickness of each layer, including the electrodes, separator, and packaging, is carefully controlled. Advanced manufacturing techniques, such as roll-to-roll processing and precision lamination, are used to ensure the uniformity and quality of the battery cells. Finally, the battery is encapsulated in a thin, flexible package, often using a laminated film material, to protect it from moisture and mechanical damage.

2.3.3 Applications

Super slim LiPo batteries have a wide range of applications, including:

Wearable Electronics: Power smartwatches, fitness trackers, smart glasses, and other wearable devices that require a thin, flexible, and rechargeable power source. The high energy density and flexibility of LiPo batteries make them ideal for these applications.

Medical Devices: Used in portable medical devices, such as blood glucose meters, pulse oximeters, and portable ECG monitors, where a compact and lightweight battery is essential. The rechargeable nature of LiPo batteries allows for repeated use, reducing the cost and environmental impact of battery replacements.

Consumer Electronics: Can be found in some thin and lightweight consumer electronics, such as Bluetooth headphones, portable speakers, and miniature drones. The super slim form factor of these batteries enables the design of sleek and portable devices.

IoT Devices: Provide power for IoT sensors, smart home devices, and other connected devices that need to be small, low-power, and long-lasting. The flexibility of LiPo batteries allows them to be integrated into the often irregularly shaped enclosures of IoT devices.

2.4 Super Slim Lithium Batteries

Super slim lithium batteries is a broad term that encompasses various lithium-based battery chemistries, including both primary (non-rechargeable) and secondary (rechargeable) types. These batteries are characterized by their use of lithium as the key component in either the anode or cathode, which gives them their high energy density and other desirable properties.

2.4.1 Characteristics

High Energy Density: Lithium-based batteries, in general, offer a high energy density compared to other battery chemistries. This allows super slim lithium batteries to store a significant amount of energy in a very thin package, making them suitable for a wide range of applications.

Wide Operating Temperature Range: Many lithium batteries can operate over a wide temperature range, from extremely cold to hot environments. This makes them suitable for use in outdoor and industrial applications where the temperature can vary significantly.

Low Self-Discharge Rate: Lithium batteries typically have a low self-discharge rate, meaning they can retain their charge for extended periods when not in use. This is important for applications where the battery may be stored for a long time before being activated.

Variety of Chemistries: There are several different lithium-based chemistries available, each with its own set of advantages and disadvantages. For example, lithium cobalt oxide (LiCoO₂) batteries offer high energy density but may have safety concerns, while lithium iron phosphate (LiFePO₄) batteries are known for their safety and long cycle life but have a slightly lower energy density.

2.4.2 Applications

Super slim lithium batteries are used in a diverse range of applications, including:

Portable Electronic Devices: Power smartphones, tablets, digital cameras, and other portable devices that require a compact and high-performance battery. The high energy density of lithium batteries allows these devices to have long battery life and slim designs.

Electric Vehicles: Although not typically in a super slim form factor for the main battery pack, some lithium batteries are used in auxiliary systems of electric vehicles, such as key fobs, sensors, and small electronic components. Additionally, research is ongoing to develop super slim and flexible lithium batteries for future wearable and integrated electronic systems in vehicles.

Energy Storage Systems: Can be used in small-scale energy storage systems, such as those for solar-powered devices or backup power supplies. The high energy density and long cycle life of some lithium batteries make them suitable for these applications.

Aerospace and Defense: Used in aerospace applications, such as satellites, drones, and aircraft, where weight and space are critical factors. The high energy density and reliability of lithium batteries make them ideal for powering the electronics and propulsion systems of these vehicles. In defense applications, they are used in communication devices, night vision equipment, and other military gear.

3. Advantages of Super Slim Batteries

3.1 Space Efficiency

The most obvious advantage of super slim batteries is their ability to save space. In modern electronic devices, where every millimeter counts, super slim batteries allow for more compact designs without sacrificing battery capacity. This is crucial for wearable electronics, where a bulky battery would make the device uncomfortable to wear, and for smart cards and RFID tags, where space is extremely limited.

3.2 Lightweight Construction

Super slim batteries are typically lightweight, which reduces the overall weight of the devices they power. This is important for portable electronics, as a lighter device is easier to carry and use for extended periods. In applications like aerospace and defense, where weight directly affects fuel consumption and performance, the lightweight nature of super slim batteries is a significant advantage.

3.3 Design Flexibility

The flexibility in shape and size offered by some super slim batteries, such as LiPo batteries, allows for greater design freedom. Manufacturers can create devices with unique form factors, curved surfaces, and irregular shapes, which can enhance the user experience and differentiate their products in the market.

3.4 High Energy Density in a Thin Package

Despite their thin profile, super slim lithium batteries can offer a high energy density. This means that they can store a relatively large amount of energy in a small volume, enabling devices to operate for longer periods between charges. This is particularly important for applications where frequent battery replacement is not practical, such as in medical implants or remote sensors.

4. Challenges of Super Slim Batteries

4.1 Manufacturing Complexity

The manufacturing of super slim batteries is a complex process that requires high precision and advanced technology. The thin layers of electrodes, separators, and packaging need to be carefully fabricated and assembled to ensure good battery performance and reliability. Any defects in the manufacturing process can lead to reduced battery capacity, shorter cycle life, or even safety issues.

4.2 Cost

Super slim batteries often involve the use of specialized materials and advanced manufacturing techniques, which can increase their production cost compared to traditional batteries. This cost factor can be a limiting factor in their widespread adoption, especially in price-sensitive applications. However, as manufacturing processes improve and economies of scale are achieved, the cost of super slim batteries is expected to decrease over time.

4.3 Safety Concerns

Although super slim batteries, especially those based on lithium chemistries, are generally considered to be safe, there are still some safety concerns associated with their use. Overcharging, over-discharging, short-circuiting, or physical damage to the battery can lead to thermal runaway, which can result in fire or explosion. Therefore, proper battery management systems and safety measures are essential to ensure the safe operation of super slim batteries.

4.4 Limited Capacity for Some Applications

Due to their thin form factor, super slim batteries typically have a limited capacity compared to larger batteries. This can be a challenge in applications that require high power consumption or long operating times between charges. Manufacturers need to carefully balance the battery size, capacity, and performance requirements of the specific application.

5. Future Developments and Trends

5.1 Advancements in Battery Chemistry

Ongoing research in battery chemistry is focused on developing new materials and chemistries that can further improve the energy density, power output, and safety of super slim batteries. For example, the development of solid-state lithium batteries, which use a solid electrolyte instead of a liquid or gel electrolyte, has the potential to offer even higher energy density, improved safety, and longer cycle life.

5.2 Improved Manufacturing Techniques

Advancements in manufacturing techniques, such as 3D printing, nanotechnology, and additive manufacturing, are expected to enable the more efficient and cost-effective production of super slim batteries. These techniques can help to reduce manufacturing defects, improve battery consistency, and increase production throughput. Additionally, they may allow for the fabrication of batteries with more complex shapes and structures, further enhancing their design flexibility.

5.3 Integration with Energy Harvesting Technologies

To further extend the battery life of super slim devices, there is a growing trend towards integrating these batteries with energy harvesting technologies, such as solar cells, thermoelectric generators, and kinetic energy harvesters. These energy harvesting systems can supplement the battery power, reducing the need for frequent recharging and improving the overall energy efficiency of the device.

5.4 Enhanced Battery Management Systems

The development of advanced battery management systems (BMS) is crucial for ensuring the safe and efficient operation of super slim batteries. BMS can monitor battery parameters, such as voltage, current, and temperature, and control the charging and discharging processes to prevent overcharging, over-discharging, and other abnormal conditions. Future BMS are expected to be more intelligent and adaptive, capable of optimizing battery performance based on the specific usage patterns of the device.

6. Conclusion

Super slim batteries have revolutionized the field of energy storage by providing compact, lightweight, and high-performance power solutions for a wide range of modern electronic devices. Whether it's the non-rechargeable LiMnO₂ batteries in smart cards, the flexible LiPo batteries in wearable electronics, or the various lithium-based batteries in portable consumer devices, these super slim power sources are enabling the development of smaller, more portable, and more innovative products.

Despite facing challenges such as manufacturing complexity, cost, safety concerns, and limited capacity, ongoing research and development efforts are driving advancements in battery chemistry, manufacturing techniques, and battery management systems. These developments are expected to lead to further improvements in the energy density, power output, safety, and cost-effectiveness of super slim batteries, opening up new possibilities for innovation in technology. As the demand for ever-smaller and more efficient electronic devices continues to grow, super slim batteries will play an increasingly vital role in powering the future.