Special shaped Lipo battery, special shaped LiMNO2 battery and ultra-thin battery pack solutions

Special shaped Lipo battery, special shaped LiMNO2 battery and ultra-thin battery pack solutions

In the rapidly evolving world of portable electronics and wearable devices, the demand for specialized, efficient, and reliable battery solutions has grown exponentially. Special shaped Lipo batteries, special shaped LiMnO₂ batteries, ultra-thin battery packs, custom LiMnO₂ batteries, and custom ultra-thin batteries are some of the most innovative solutions that have emerged to meet these demands. This article delves into the technology behind these batteries, their applications, and the challenges faced in their development and integration.

1. Introduction to Special-Shaped Battery Technology

As consumer electronics become more diverse and specialized, traditional battery formats often fail to provide the necessary flexibility and efficiency. Special-shaped batteries, such as Lipo (Lithium Polymer) and LiMnO₂ (Lithium Manganese Oxide), offer unique advantages in terms of their ability to be customized and conform to irregular shapes and sizes. These batteries are not limited by the constraints of traditional cylindrical or prismatic cells, allowing for more freedom in design and integration.

2. Lipo Battery Technology

Lipo batteries, also known as Lithium-ion Polymer batteries, are a type of rechargeable battery that uses a polymer electrolyte instead of the traditional liquid electrolyte. This polymer electrolyte gives Lipo batteries several advantages over traditional Lithium-ion batteries. Firstly, they are lighter and more flexible, allowing for their use in a wider range of applications. Secondly, they have a higher energy density, meaning they can store more energy per unit weight or volume.

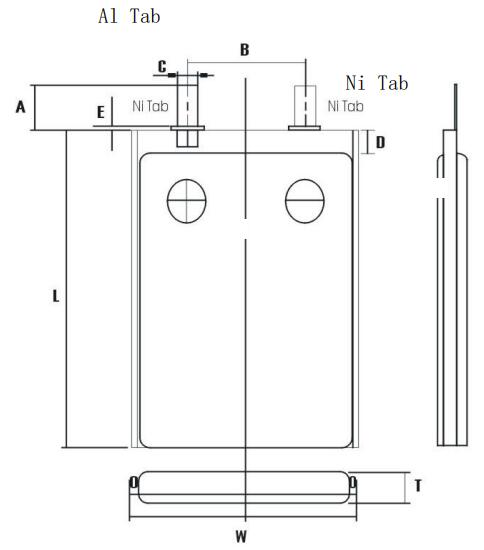

Special shaped Lipo batteries are particularly useful in devices that require irregular shapes or contours. They can be custom-made to fit into tight spaces or conform to the curves of wearable devices. This flexibility has made them popular in consumer electronics such as smartphones, tablets, and wearables.

3. LiMnO₂ Battery Technology

LiMnO₂ batteries, on the other hand, utilize Lithium Manganese Oxide as the positive electrode material. These batteries are known for their high safety, stability, and cost-effectiveness. They have a lower energy density compared to Lipo batteries but are often favored for applications where safety is a priority.

Special shaped LiMnO₂ batteries offer similar advantages to Lipo batteries in terms of flexibility and conformability. However, their safety profile makes them ideal for use in medical devices, industrial equipment, and other applications where failure could have severe consequences.

4. Ultra-Thin Battery Technology

Ultra-thin battery packs are designed to provide power to devices that require an extremely low profile. These batteries are typically very thin and lightweight, allowing them to be integrated into devices with minimal impact on the overall dimensions. Ultra-thin batteries are commonly used in smartwatches, fitness trackers, and other wearable electronics.

The key challenge in developing ultra-thin batteries is maintaining energy density while reducing thickness. Manufacturers achieve this by using advanced materials and cell design techniques that maximize the utilization of space within the battery pack. Custom ultra-thin batteries allow for further optimization based on the specific requirements of the end-use application.

5. Custom Battery Solutions

Custom battery solutions are essential for many specialized applications where off-the-shelf batteries fail to meet the specific needs of the device. Custom LiMnO₂ batteries and custom ultra-thin batteries are tailored to meet the unique requirements of the application, including shape, size, capacity, voltage, and discharge rate.

The process of developing custom batteries typically involves close collaboration between the battery manufacturer and the device manufacturer. The device manufacturer provides detailed specifications and requirements, while the battery manufacturer designs and produces a battery that meets those specifications. This collaboration ensures that the battery perfectly fits the needs of the device, optimizing performance and reliability.

6. Challenges and Opportunities in Special-Shaped Battery Technology

While special-shaped battery technology offers numerous advantages, there are also several challenges that need to be addressed. One of the main challenges is ensuring the safety and stability of these batteries during operation. Special shaped batteries can be more susceptible to mechanical stress and deformation, which can affect their performance and reliability.

Another challenge is the cost of custom battery solutions. Custom batteries require specialized design, manufacturing, and testing, which can increase their overall cost. However, the benefits of having a battery that perfectly fits the needs of the device often outweigh the additional cost.

Despite these challenges, there are significant opportunities for growth and innovation in special-shaped battery technology. The increasing demand for portable and wearable electronics, as well as the development of new applications and technologies, is driving the need for more efficient and reliable battery solutions. Manufacturers are continuously investing in research and development to improve the performance, safety, and cost-effectiveness of these batteries.