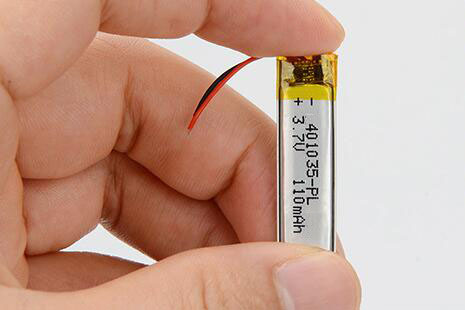

Ultra-Thin battery and ultra thin Lithium-Ion Polymer Battery 103053 95mAh

Ultra-Thin battery and ultra thin Lithium-Ion Polymer Battery 103053 95mAh

1. Introduction to Ultra-Thin Battery Technology

In the era of miniaturized electronics, the demand for compact, high-performance energy storage solutions has surged. Ultra-thin lithium-ion polymer batteries, ultrathin Lipo battery such as the 103053 95mAh model, represent a breakthrough in power density and form factor optimization. Designed for applications where space is at a premium, these batteries combine advanced materials science with precision engineering to deliver reliable energy in sleek, lightweight packages. This article delves into the technical specifications, performance characteristics, safety features, and applications of the 103053 95mAh battery, highlighting its role in enabling next-generation devices.

2. Technical Specifications Overview

The 103053 95mAh ultrathin Lipo battery is engineered to meet the rigorous demands of modern portable electronics. Its key specifications include:

Nominal Voltage: 3.7V (standard for lithium-ion chemistries).

Capacity: 95mAh (milliampere-hours), optimized for balanced energy and size.

Dimensions: 1.0mm (thickness) × 30mm (width) × 53mm (height).

Charging/Discharging Parameters:

Standard Current: 0.2C (19mA) for both charging and discharging.

Max Charging Current: 1C (95mA).

Max Continuous Discharging Current: 1C (95mA).

Pulse Discharging Current: 1.5C (142.5mA).

Cut-Off Voltages: 3.0V (discharge termination) / 4.2V (charge termination).

Cycle Life: 500 cycles (80% capacity retention).

Operational Temperature Ranges:

Charging: 0°C–45°C.

Discharging: -20°C–60°C.

Storage: -10°C–35°C (optimal at 20°C ±5°C).

Quality Standards: Scratch-free, distortion-free, contamination-free, and leakage-resistant.

These parameters position the battery as a versatile solution for devices requiring thin profiles without compromising energy efficiency.

3. Design and Construction

3.1 Ultra-Thin Form Factor

At just 1.0mm thick, the 103053 battery achieves a remarkable thickness-to-capacity ratio. This is made possible by:

Polymer Electrolyte: Replaces liquid electrolytes with a solid-state polymer matrix, reducing leakage risks and enabling flexible packaging.

Stacked Electrode Architecture: Multi-layer electrode designs maximize active material within minimal space.

Advanced Cell Stacking: Precision assembly techniques ensure uniform current distribution across layers.

3.2 Material Innovations

Cathode Chemistry: Likely uses lithium cobalt oxide (LiCoO₂) or lithium nickel manganese cobalt oxide (NMC) for high energy density.

Anode: Graphite or silicon-carbon composite for stable lithium intercalation.

Separator: Ceramic-coated polyolefin for thermal stability and ion permeability.

3.3 Packaging

The battery adopts a soft pouch cell design, which conforms to device geometries while minimizing weight. Aluminum-laminated foil encasing provides barrier protection against moisture and oxygen.

4. Performance Analysis

4.1 Energy Density and Efficiency

Gravimetric Energy Density: ~180 Wh/kg (typical for lithium-ion polymer).

Volumetric Energy Density: ~450 Wh/L, critical for thin-profile devices.

Coulombic Efficiency: >99% (minimal self-discharge during storage).

4.2 Charging and Discharging Dynamics

Standard Charging (0.2C): Safe for routine use, minimizing stress on electrodes.

Rapid Charging (1C): Enables quick top-ups but may reduce cycle life if overused.

Pulse Discharge (1.5C): Supports high-current bursts for motors or wireless transmission.

4.3 Temperature Performance

Low-Temperature Operation: Discharge capability down to -20°C ensures functionality in cold environments.

High-Temperature Tolerance: Discharging up to 60°C suits industrial or outdoor applications.

Thermal Management: Polymer electrolytes mitigate thermal runaway risks compared to liquid counterparts.

5. Safety Features

5.1 Protection Mechanisms

Overcharge Protection: Internal circuitry or BMS (Battery Management System) halts charging at 4.2V.

Overdischarge Protection: Prevents cell damage by cutting off at 3.0V.

Short-Circuit Protection: Rapid current limiting to avoid thermal events.

5.2 Mechanical Stability

Flexible Pouch Design: Resists puncture and deformation under stress.

Vibration/Shock Resistance: Polymer electrolytes reduce mechanical strain during movement.

5.3 Environmental Durability

Humidity Tolerance: Laminated foil packaging blocks moisture ingress.

Chemical Resistance: Protects against common solvents and corrosive substances.

6. Applications and Use Cases

6.1 Consumer Electronics

Wearables: Smartwatches, fitness trackers, and AR glasses benefit from the thin, lightweight design.

True Wireless Earbuds: Enables compact charging cases with extended playback time.

Medical Devices: Portable glucose monitors and patch-style health sensors.

6.2 Industrial Applications

IoT Sensors: Ultra-low profile for embedded environmental or structural monitoring.

RFID Tags: Thin batteries extend the operational lifespan of passive tags.

Miniature Drones: Lightweight power for micro-UAVs used in surveying or inspection.

6.3 Automotive and Mobility

Key Fobs: Slim design integrates seamlessly into modern car keys.

E-Bike Displays: Powers compact screens without bulky battery compartments.

7. Cycle Life and Longevity

Rated Cycle Life: 500 cycles with 80% capacity retention.

Depth of Discharge (DoD): Optimal performance at 20–80% DoD cycles.

Aging Factors:

Temperature: Storage at 20°C ±5°C minimizes degradation.

Charge/Discharge Rates: Frequent 1C cycling may reduce lifespan.

8. Environmental Impact and Sustainability

Recyclability: Lithium-ion batteries are recyclable, with recovery rates for cobalt and nickel exceeding 90%.

Low Self-Discharge: Minimizes energy waste during storage.

RoHS Compliance: Adheres to restrictions on hazardous materials.

9. Competitive Advantages

Thickness: Thinner than comparable lithium-ion chemistries.

Light Weight: Polymer construction reduces overall device weight.

Design Flexibility: Customizable shapes and sizes for OEM integration.

Cost-Effectiveness: Balances performance and price for mid-range applications.

10. Testing and Quality Control

IEC 62133 Certification: Ensures compliance with international safety standards.

UN 38.3 Testing: Validates transport safety for lithium-ion batteries.

In-House Testing:

Mechanical Shock: 1m drop test without performance loss.

Vibration: 24-hour vibration test at 5–500Hz.

Thermal Cycling: -40°C to 70°C temperature shocks.

11. Future Trends and Innovations

Solid-State Batteries: Potential for even thinner designs with enhanced safety.

Silicon Anodes: Next-gen anodes could boost capacity by 30–50%.

Flexible Batteries: Integration into bendable devices like foldable smartphones.

12. Conclusion

The 103053 95mAh ultra-thin lithium-ion polymer battery represents a pinnacle of miniaturization in energy storage. Its combination of high energy density, robust safety features, and wide operational temperature range makes it ideal for diverse applications—from consumer wearables to industrial IoT. As devices continue to shrink, this battery serves as a critical enabling technology, bridging the gap between form factor and functionality. For manufacturers seeking reliable, space-efficient power solutions, the 103053 model offers a compelling balance of performance, safety, and versatility in an era where every millimeter matters.