ER14250S 3.6V High Temperature battery 150°C Low Self-discharge Rate 1/2AA Size for Medical Equipment

ER14250S 3.6V High Temperature battery 150°C Low Self-discharge Rate 1/2AA Size for Medical Equipment

1. Introduction

1.1 Battery Basics in the Modern World

In today's highly technological era, batteries are the unsung heroes powering our modern lifestyle. They are omnipresent, from the smallest wearable devices like smartwatches that monitor our health metrics throughout the day to large - scale energy storage systems crucial for integrating renewable energy sources such as solar and wind into the power grid.

Consider our daily routine. We wake up to an alarm clock powered by a battery, check our smartphones (also battery - operated) for messages and news, and then head to work in a car with a battery - assisted ignition system. In the office, backup uninterruptible power supply (UPS) systems, which rely on batteries, ensure that our computers and important data are safe during power outages. At home, remote - controlled devices like TVs, air conditioners, and even some kitchen appliances use batteries.

Batteries are classified into different types, each with its own set of characteristics. Rechargeable batteries, such as lithium - ion (Li - ion), nickel - metal hydride (Ni - MH), and lead - acid, are widely used in applications where repeated use is required, like in electric vehicles (EVs) and portable electronics. Li - ion batteries, for example, are favored for their high energy density, long cycle life, and relatively low self - discharge rate. They power most of our smartphones, laptops, and tablets, enabling us to work, communicate, and be entertained on - the - go.

On the other hand, non - rechargeable (primary) batteries have their own niche. They are often used in applications where long - term, low - current draw is needed, or where the cost of a rechargeable system is not justifiable. Alkaline batteries are common in household items like flashlights, remote controls, and some toys. However, in more specialized applications, other non - rechargeable battery chemistries come into play. This leads us to the focus of this article, the ER14250S 3.6V high - temperature non - rechargeable lithium battery, which is making waves in specific industries due to its unique set of features.

1.2 The Spotlight on ER14250S

The ER14250S is a remarkable non - rechargeable high temperature battery that has carved out a significant role in various high - demand applications. The "ER" in its model name typically indicates a lithium - thionyl chloride battery chemistry, LiSOCL2 battery, which is known for its high energy density, long shelf life, and excellent performance in extreme conditions.

1. Key Parameters

Voltage: It has a nominal voltage of 3.6V. This relatively high and stable voltage output makes it suitable for powering devices that require a consistent power supply. Many electronic components and circuits are designed to operate optimally within a specific voltage range, and the 3.6V output of the ER14250S can directly power or be used in combination with voltage regulators to meet the requirements of different devices.

Capacity: With a capacity of 600mAh (milliampere - hours), it stores a significant amount of electrical energy. The capacity determines how long the battery can power a device under a given load. For example, if a device draws a continuous current of 1mA, the ER14250S could potentially power it for 600 hours (600mAh divided by 1mA), although in real - world scenarios, factors like battery discharge characteristics and device power consumption profiles may affect the actual runtime.

Size: It has a 1/2AA size, which is a compact form factor. Measuring approximately 14.5mm in diameter and 25.6mm in height, this size makes it suitable for use in devices where space is at a premium, such as small - scale medical equipment, miniature sensors, and some types of industrial monitoring devices. The compact size also allows for easy integration into existing product designs without significant re - engineering.

Temperature Range: One of the most outstanding features of the ER14250S is its ability to operate at high temperatures, up to 150°C. This high - temperature tolerance sets it apart from many other battery chemistries. In contrast, common rechargeable Li - ion batteries typically have a maximum operating temperature of around 60 - 80°C. The ER14250S's high - temperature performance makes it ideal for use in applications where extreme heat is present, such as in oil and gas exploration, down - hole drilling equipment, and geothermal monitoring systems.

2. Low Self - Discharge Rate

The ER14250S also boasts a low self - discharge rate. Self - discharge is the rate at which a battery loses its charge when not in use. A low self - discharge rate means that the battery can maintain its stored energy for a long time when idle. For the ER14250S, this is a crucial advantage, especially in applications where the battery may be stored for extended periods before use, or in devices that are intermittently used. For example, in emergency medical devices that need to be ready for use at a moment's notice, a low self - discharge rate ensures that the battery will have sufficient charge when it is finally required. Table 1 below provides a comparison of the self - discharge rates of the ER14250S with some other common battery chemistries:

This low self - discharge rate not only saves energy but also increases the reliability and lifespan of the battery in long - term storage or intermittent - use applications.

2. Technical Characteristics of ER14250S

2.1 High - Temperature Performance

2.1.1 Temperature Tolerance Range

The ER14250S stands out prominently for its exceptional temperature tolerance range, with the ability to operate efficiently at temperatures as high as 150°C. This high - temperature capability is a game - changer in many industrial applications. In contrast, most common rechargeable lithium - ion batteries have a much more restricted operating temperature range. For instance, a typical lithium - ion battery used in a smartphone or laptop has a maximum operating temperature of around 60 - 80°C. Beyond this limit, the battery may experience significant performance degradation, reduced cycle life, and in extreme cases, safety issues such as thermal runaway, which can lead to fires or explosions.

In the oil and gas industry, down - hole drilling equipment operates in extremely harsh environments where temperatures can soar well above 100°C. Traditional batteries would quickly fail under such conditions. The ER14250S, on the other hand, thrives in these high - temperature settings. It can power sensors that monitor parameters like pressure, temperature, and fluid flow deep within the earth's crust, ensuring continuous and reliable data collection. Table 2 below provides a comparison of the high - temperature tolerance of the ER14250S with some other common battery chemistries:

This wide temperature tolerance range makes the ER14250S suitable for a plethora of applications in industries such as aerospace, where components are exposed to extreme temperatures during flight; automotive, especially in high - performance engines or in - vehicle electronics near heat - generating components; and in industrial furnaces or ovens where high - temperature monitoring and control systems require a reliable power source.

2.1.2 Impact of High Temperature on Performance

While the ER14250S can operate at high temperatures, it's essential to understand how these extreme conditions impact its performance. At high temperatures, the battery's electrochemical reactions are accelerated. This can lead to both positive and negative effects on its performance.

Positive Effects:

Enhanced Discharge Performance: In some cases, the increased temperature can reduce the internal resistance of the battery. As a result, the battery can deliver higher currents more efficiently. For example, in a high - temperature industrial sensor application where the sensor needs to transmit data in short, high - power bursts, the ER14250S can provide the necessary power with less voltage drop due to its reduced internal resistance at high temperatures. This allows for faster data transfer and more accurate readings, as the sensor can operate closer to its optimal power levels.

Negative Effects:

Capacity Degradation: Prolonged exposure to high temperatures can cause a decrease in the battery's capacity. The high - temperature - induced acceleration of electrochemical reactions can lead to the formation of side - products and the degradation of the active materials within the battery. For instance, the lithium - thionyl chloride chemistry in the ER14250S may experience the decomposition of thionyl chloride at high temperatures over time. This decomposition can reduce the amount of available reactants for the main battery reaction, thus decreasing the overall capacity of the battery. A study showed that after continuous operation at 150°C for 100 hours, the ER14250S may experience a capacity loss of approximately 10 - 15% compared to its initial capacity at room temperature.

Voltage Instability: High temperatures can also affect the voltage stability of the ER14250S. The battery's voltage may fluctuate more significantly at high temperatures, which can be a concern for devices that require a very stable power supply. In precision medical equipment, even a slight voltage fluctuation could potentially affect the accuracy of diagnostic readings or the proper functioning of delicate electronic components. To mitigate this issue, additional voltage regulation circuitry may be required when using the ER14250S in such applications at high temperatures.

2.2 Non - rechargeable Feature

2.2.1 Principle of Non - rechargeability

The ER14250S is a non - rechargeable (primary) battery, and its non - rechargeability is rooted in its underlying electrochemical reactions. In a lithium - thionyl chloride (LiSOCl₂) battery like the ER14250S, the main chemical reaction during discharge is as follows:

During discharge, lithium atoms from the anode lose electrons and become lithium ions (

The reason it cannot be recharged effectively is that the products of the discharge reaction, such as lithium chloride, sulfur, and sulfur dioxide, are difficult to convert back to their original reactant forms through an external electrical current. The formation of solid - state products like lithium chloride and sulfur can lead to physical and chemical changes within the battery that are not easily reversible. For example, the lithium chloride may deposit on the electrodes in a way that disrupts the normal ion - transfer pathways. Additionally, the reaction products may cause changes in the electrolyte composition and properties, further impeding the reverse reaction.

2.2.2 Comparison with Rechargeable Batteries

When comparing the non - rechargeable ER14250S with rechargeable batteries, several factors come into play, and their suitability varies depending on the application scenario.

Advantages in Some Applications:

Cost - Effectiveness in Low - Usage Applications: For applications where the battery is used infrequently or has a very long service life with low - power consumption, the non - rechargeable ER14250S can be more cost - effective. Consider a remote - monitoring sensor in a forest that is used to detect environmental parameters like humidity and temperature. The sensor may only need to transmit data once a day or even less frequently. In such a case, the cost of a rechargeable battery system, which includes the battery, charger, and associated circuitry, may be unjustifiable. The ER14250S, with its long shelf life and low self - discharge rate, can provide the necessary power for an extended period without the need for complex and costly recharging infrastructure.

Simplicity and Reliability: Non - rechargeable batteries are generally simpler in design compared to rechargeable ones. They do not require complex battery management systems (BMS) to prevent over - charging, over - discharging, and thermal runaway, which are crucial for rechargeable batteries. In applications where simplicity and high reliability are of utmost importance, such as in some military or emergency - response devices, the ER14250S can offer a more straightforward and dependable power solution. There is no risk of BMS failure, which could potentially render a rechargeable battery system inoperable.

Disadvantages in Other Applications:

Long - Term Cost in High - Usage Applications: In applications with high - frequency or continuous power consumption, rechargeable batteries are more cost - effective in the long run. For example, in an electric vehicle (EV) that requires large amounts of power for propulsion, using non - rechargeable batteries would be prohibitively expensive due to the need for frequent battery replacements. Rechargeable lithium - ion batteries in EVs can be charged hundreds or even thousands of times, reducing the overall cost per unit of energy consumed.

Limited Energy Supply: Once the non - rechargeable ER14250S is depleted, it must be replaced. This can be a significant drawback in applications where continuous operation is essential and battery replacement is difficult or impossible, such as in implanted medical devices. In contrast, rechargeable batteries can be re - energized, providing a continuous power source as long as a charging infrastructure is available. Table 3 below summarizes the key differences between non - rechargeable (ER14250S) and rechargeable batteries:

| Comparison Aspect | Non - rechargeable (ER14250S) | Rechargeable (e.g., Lithium - Ion) |

| ---- | ---- | ---- |

| Cost in Low - Usage Applications | Lower initial cost, cost - effective | Higher initial cost, may not be cost - effective |

| Cost in High - Usage Applications | High long - term cost due to replacements | Lower long - term cost with recharging |

| Design Complexity | Simple, no complex BMS | Complex, requires BMS for safety and performance |

| Energy Supply Continuity | Limited, needs replacement when depleted | Continuous with recharging |

2.3 Low Self - discharge Rate

2.3.1 The Significance of Low Self - discharge

A low self - discharge rate is one of the most valuable features of the ER14250S, with far - reaching implications for its long - term storage and use. Self - discharge is the process by which a battery loses its stored charge over time when not in use. For the ER14250S, having a self - discharge rate of less than 1% per month is a remarkable advantage.

In applications where the battery needs to be stored for extended periods before use, such as in emergency medical equipment, backup power systems for critical infrastructure, or military ordnance, a low self - discharge rate ensures that the battery will have sufficient charge when it is finally required. For example, in a defibrillator that is stored in a hospital emergency room, it must be ready to deliver a high - voltage shock to a patient's heart at a moment's notice. If the battery powering the defibrillator had a high self - discharge rate, it could potentially be depleted when needed, putting the patient's life at risk.

Moreover, in devices that are used intermittently, like remote - controlled sensors in industrial monitoring systems, a low self - discharge rate means that the battery can maintain its charge between uses. This reduces the frequency of battery replacements, saving both time and cost. Table 4 below shows the impact of self - discharge rates on the charge retention of different batteries over a one - year period:

2.3.2 Mechanism of Low Self - discharge

The low self - discharge rate of the ER14250S can be attributed to its unique electrochemical structure and the properties of its components.

Electrochemical Structure:

The lithium - thionyl chloride chemistry of the ER14250S has a relatively stable electrochemical equilibrium. The anode, made of lithium, and the cathode, involving thionyl chloride, do not readily react with each other in the absence of an external load under normal conditions. The electrolyte, which allows the movement of lithium ions between the anode and cathode during discharge, also plays a role in minimizing self - discharge. It has a high resistance to side - reactions that could lead to the loss of charge. For example, the electrolyte is formulated in such a way that it inhibits the formation of dendrites on the lithium anode. Dendrites can cause internal short - circuits in the battery, which would accelerate self - discharge.

Component Properties:

The materials used in the battery's construction are carefully selected to reduce self - discharge. The separator, which physically separates the anode and cathode, has excellent ion - conducting properties while preventing the direct contact of the active materials. This reduces the likelihood of spontaneous chemical reactions that could lead to self - discharge. Additionally, the battery casing is designed to be highly impermeable to moisture and other contaminants. Moisture can react with the battery components and initiate unwanted chemical reactions, increasing self - discharge. The high - quality, hermetically sealed casing of the ER14250S ensures that the internal components are protected from the external environment, contributing to its low self - discharge rate.

2.4 1/2AA Size and 600mAh Capacity

2.4.1 Size - related Advantages

The 1/2AA size of the ER14250S, with its compact dimensions of approximately 14.5mm in diameter and 25.6mm in height, offers several distinct advantages, especially in the context of modern - day miniaturized electronic devices.

Space - Saving in Compact Devices: In small - scale medical equipment such as implantable glucose monitors or miniature pacemakers, space is at an absolute premium. The 1/2AA size of the ER14250S allows it to fit snugly into these devices without taking up excessive space. This is in contrast to larger - sized batteries, which would either require the device to be bulkier or would not fit at all. For example, a traditional AA - sized battery has a diameter of about 14.5mm and a height of around 50.5mm. If an implantable medical device were to use an AA - sized battery, it would not only be difficult to implant due to its size but also would require a much larger and more invasive surgical procedure. The compact 1/2AA size of the ER14250S enables these medical devices to be smaller, more comfortable for the patient, and less invasive to implant.

Easy Integration into Existing Designs: Many existing electronic device designs are already optimized to accommodate specific battery sizes. The 1/2AA size of the ER14250S makes it easier to integrate into these designs without significant re - engineering. In industrial monitoring sensors that are designed to be small and unobtrusive, the 1/2AA size can be easily incorporated into the existing sensor housing. This reduces the development time and cost associated with redesigning the device to fit a different - sized battery. Table 5 below provides a comparison of the dimensions of the 1/2AA - sized ER14250S with other common battery sizes:

2.4.2 Capacity Analysis

With a capacity of 600mAh, the ER14250S can provide a significant amount of electrical energy to power various devices. The capacity of a battery determines how long it can supply power to a device under a given load.

Meeting Power Demands in Different Applications: In applications with low - power - consuming devices, the 600mAh capacity of the ER14250S can provide an extended operating time. For example, a wireless temperature - humidity sensor that draws a continuous current of 0.1mA can be powered by the ER14250S for up to 6000 hours (600mAh divided by 0.1mA), which is approximately 250 days. This long - lasting power supply is crucial for applications where frequent battery replacements are not feasible, such as in environmental monitoring stations located in remote areas.

However, in applications with higher - power - consuming devices, the battery's capacity may need to be carefully considered. For instance, if a small - scale medical diagnostic device draws a continuous current of 10mA, the ER14250S would be able to power it for 60 hours (600mAh divided by 10mA). In such cases, depending on the usage pattern of the device, the battery may need to be replaced more frequently. But considering its non - rechargeable nature and high - temperature capabilities, it can still be a viable option in applications where rechargeable batteries are not suitable due to temperature constraints or the need for a simple, maintenance - free power source. Table 6 below shows the estimated runtime of the ER14250S for different device current draw levels:

3. Chemical Principles and Structure of LiSOCl₂ Battery

3.1 Chemical Reaction in LiSOCl₂ Battery

3.1.1 Reaction Formula and Process

The chemical reaction in a lithium - thionyl chloride (LiSOCl₂) battery, such as the ER14250S, is a complex electrochemical process. The overall reaction formula is as follows:

Discharge Process Step - by - Step:

Anode Reaction: At the anode, which is made of lithium (Li), oxidation occurs. Lithium atoms lose electrons according to the reaction:. Lithium, with its low standard electrode potential of - 3.04 V (vs. standard hydrogen electrode), is highly reactive and readily donates electrons. These electrons flow through the external circuit, creating an electric current that can be used to power external devices. For example, in a medical sensor powered by the ER14250S, these electrons are harnessed to operate the sensor's circuitry and transmit data.

Cathode Reaction: At the cathode, the reduction of thionyl chloride () takes place. The electrons from the anode flow to the cathode through the external circuit. Here, accepts the electrons and reacts with the lithium ions () that have migrated through the electrolyte. The reaction at the cathode can be considered in two steps.

During the discharge process, the continuous flow of electrons from the anode to the cathode through the external circuit and the movement of lithium ions through the electrolyte maintain the electrical current, providing power to the connected device. As the reaction progresses, the lithium at the anode is gradually consumed,eventually leading to the depletion of the battery's energy storage capacity.

3.1.2 Role of Each Component in the Reaction

Lithium (Li): As the anode material, lithium plays a crucial role in the battery's operation. Its high reactivity and low standard electrode potential make it an excellent electron donor. Lithium's low atomic weight also contributes to the high energy density of the LiSOCl₂ battery. For every mole of lithium that reacts, one mole of electrons is released, providing the electrical charge necessary for the battery to function. However, lithium's reactivity also poses some challenges. It can react with impurities in the electrolyte or with moisture if the battery's seal is compromised, which can lead to self - discharge or other performance - degradation issues.

Thionyl Chloride : Thionyl chloride serves a dual function in the LiSOCl₂ battery. It is both the electrolyte solvent and the main active material at the cathode. As an electrolyte, it provides a medium for the transport of lithium ions between the anode and the cathode. Its high dielectric constant helps in the dissociation of lithium salts, facilitating the movement of lithium ions. As an active material, it accepts electrons at the cathode and undergoes a reduction reaction to form the products, with a typical nominal voltage of 3.6V for LiSOCl₂ batteries.

Lithium Chloride (LiCl): Lithium chloride is a reaction product of the battery's discharge process. It is formed when lithium ions combine with chloride ions at the cathode.

Sulfur (S) and Sulfur Dioxide : These are also reaction products. Sulfur and sulfur dioxide dissolve in the excess thionyl chloride electrolyte. The presence of SO2 can cause an increase in the internal pressure of the battery during discharge, especially if a large amount is produced. In some cases, batteries are designed with safety features, such as pressure - relief valves, to handle this potential increase in pressure. The sulfur can also have an impact on the battery's performance. Although it is a relatively inert product in the context of the main battery reaction, its presence in the electrolyte can affect the electrolyte's properties and the overall electrochemical kinetics of the battery over long - term use.

3.2 Internal Structure of the Battery

3.2.1 Components of the Battery Structure

Anode: The anode of the LiSOCl₂ battery is typically made of metallic lithium. Lithium is chosen for its high theoretical specific capacity (3860 mAh/g) and low standard electrode potential, which allows the battery to produce a high voltage. The anode is usually in the form of a thin film or a compacted powder - based structure. In a cylindrical - shaped ER14250S battery, the lithium anode may be formed as a layer lining the inner wall of the battery casing.

Cathode: The cathode consists of a mixture of carbon - based materials and the active cathode material, which is thionyl chloride . The carbon component, often in the form of carbon black or graphite, provides electrical conductivity to the cathode. It also has a high surface area, which increases the contact area between the thionyl chloride and the electrons flowing from the external circuit during the discharge process. The thionyl chloride is absorbed or impregnated into the porous carbon structure. The cathode is designed to have a high porosity to maximize the utilization of the active material and to allow for the easy diffusion of lithium ions and the reaction products.

Electrolyte: The electrolyte in a LiSOCl₂ battery is a solution of lithium salts, such as lithium aluminum chloride , dissolved in thionyl chloride. The electrolyte serves as the medium for the transport of lithium ions between the anode and the cathode. It enables the flow of charge within the battery, completing the electrical circuit. The choice of lithium salt and its concentration in the thionyl chloride solvent can affect the electrolyte's conductivity, viscosity, and stability, all of which have an impact on the battery's overall performance.

Separator: A separator is placed between the anode and the cathode. It is a porous membrane made of materials such as polypropylene (PP), polyethylene (PE), or glass - fiber - based materials. The separator's main function is to prevent direct physical contact between the anode and the cathode, which could lead to a short - circuit. At the same time, it allows the passage of lithium ions through its pores, facilitating the ionic conduction necessary for the battery's operation. The separator's pore size, porosity, and mechanical strength are critical parameters. A too - small pore size can impede ion transport, increasing the battery's internal resistance, while a too - large pore size may not effectively prevent short - circuits.

Battery Casing: The battery casing is usually made of a metal, such as stainless steel, or a high - strength plastic. In the case of the ER14250S, a metal casing may be used for its excellent mechanical strength and ability to withstand the internal pressure generated during the battery's operation. The casing provides physical protection to the internal components of the battery, preventing damage from external mechanical forces. It also serves as a hermetic seal, preventing the ingress of moisture and oxygen from the external environment, which could react with the battery components and degrade the battery's performance. In some designs, the casing may also be electrically conductive and serve as an electrode terminal.

3.2.2 How the Structure Affects Performance

Separator and Short - Circuit Prevention: The separator is crucial for the battery's safety and stable operation. By physically separating the anode and the cathode, it effectively prevents short - circuits. In a LiSOCl₂ battery, if the anode and cathode were to come into direct contact, a large current would flow instantaneously, leading to overheating, a rapid drop in voltage, and potentially even a thermal runaway or explosion. For example, in a medical implant powered by a LiSOCl₂ battery, a short - circuit could not only render the device inoperable but also pose a serious risk to the patient's health. The separator's ion - conducting properties also play a vital role in maintaining the battery's performance. It allows lithium ions to move freely between the anode and the cathode, enabling the electrochemical reactions to occur. If the separator has a low ion - conductivity or if its pores become blocked during the battery's life cycle, the internal resistance of the battery will increase. This increase in resistance leads to a voltage drop across the battery, reducing the power available to the external device and shortening the battery's overall runtime.

Casing and Hermetic Seal: The battery casing's hermetic seal is essential for maintaining the battery's performance over time. Moisture and oxygen from the external environment can react with the battery components. Lithium, being highly reactive, can react with moisture to form lithium hydroxide and hydrogen gas. This reaction not only consumes the active anode material but also generates gas, which can increase the internal pressure of the battery. In addition, the presence of moisture can also cause side - reactions in the electrolyte, leading to a change in its composition and properties. For example, water can react with thionyl chloride to form hydrochloric acid and sulfur dioxide, which can corrode the battery's internal components and accelerate self - discharge. The hermetic seal provided by the casing ensures that the internal components are protected from these external contaminants, preserving the battery's chemical integrity and performance.

Electrode Structure and Reactivity: The structure of the anode and cathode affects their reactivity and the overall battery performance. The high surface area of the carbon - based cathode materials increases the contact area between the thionyl chloride and the electrons, enhancing the reaction rate at the cathode. A more porous cathode structure allows for better diffusion of the reactants and products, reducing the concentration polarization within the battery. Similarly, the structure of the lithium anode can impact its performance. A smooth and uniform anode surface can reduce the formation of dendrites during the discharge process. Dendrites are needle - like growths of lithium that can form on the anode surface, especially during high - current discharge or over - discharge conditions. These dendrites can penetrate the separator and cause an internal short - circuit, reducing the battery's lifespan and safety.

4. Applications in Medical Equipment

4.1 Specific Medical Equipment Using ER14250S

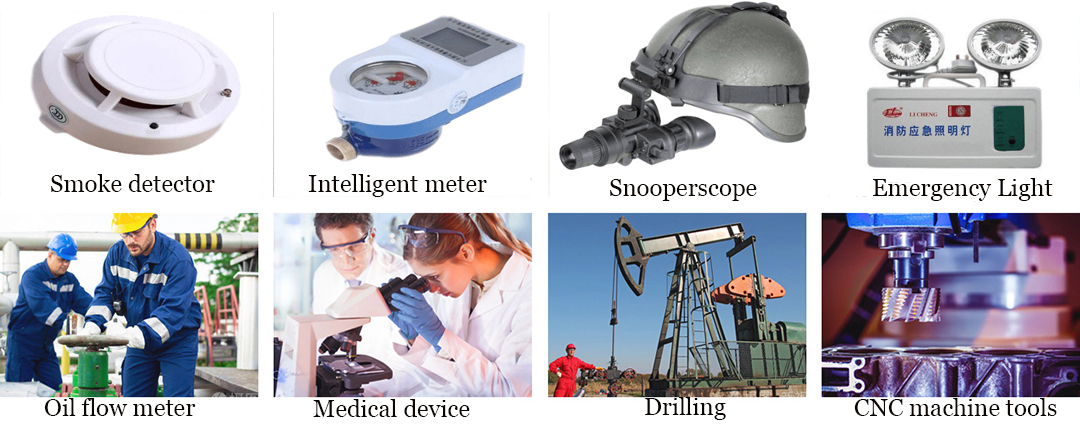

The ER14250S 3.6V high - temperature non - rechargeable lithium battery finds its application in a diverse range of medical equipment, each with its own unique requirements for power supply.

Implantable Medical Devices:

Pacemakers: These life - saving devices are implanted in patients with heart rhythm disorders. A pacemaker uses electrical impulses to regulate the heart's rhythm. The ER14250S is suitable for pacemakers due to its long - term stable power supply and compact 1/2AA size. The battery needs to power the pacemaker for several years, and the low self - discharge rate of the ER14250S ensures that it can maintain sufficient charge over this extended period. Its high - temperature tolerance is also beneficial, as the body temperature can vary slightly, and the battery must be able to function optimally within this range.

Implantable Cardioverter - Defibrillators (ICDs): ICDs are used to detect and treat life - threatening cardiac arrhythmias. They deliver electric shocks to the heart when necessary. The ER14250S provides the high - energy pulses required for the defibrillation function. Its reliability in sensitive medical environments is crucial, as any failure in the power supply could have fatal consequences for the patient.

Portable Medical Monitoring Devices:

Wearable Glucose Monitors: These devices are used by diabetic patients to continuously monitor their blood glucose levels. They are typically worn on the body and transmit data wirelessly to a receiver or a smartphone. The ER14250S's compact size allows it to be easily integrated into the small form factor of the wearable glucose monitor. Its long - lasting power supply is essential, as patients need the device to operate continuously for days or even weeks without frequent battery replacements.

Portable Electrocardiogram (ECG) Monitors: Portable ECG monitors are used for home - based or ambulatory cardiac monitoring. They record the electrical activity of the heart and can be used to detect various heart conditions. The ER14250S powers these monitors, enabling patients to carry them around comfortably while providing a stable power source for accurate ECG readings. Table 7 below summarizes some of the medical equipment using the ER14250S and their key power - related requirements:

| Medical Equipment | Key Power Requirements | Reason for Using ER14250S |

| ---- | ---- | ---- |

| Pacemakers | Long - term stable power, compact size | Low self - discharge, 1/2AA size |

| Implantable Cardioverter - Defibrillators (ICDs) | High - energy pulses, reliability | High - temperature tolerance, reliability |

| Wearable Glucose Monitors | Compact size, long - lasting power | 1/2AA size, low self - discharge |

| Portable Electrocardiogram (ECG) Monitors | Stable power, compactness | Stable voltage output, 1/2AA size |

4.2 Advantages for Medical Applications

4.2.1 Reliability in Sensitive Medical Environments

In medical environments, the reliability of the power source is of utmost importance. The ER14250S offers several features that make it highly reliable in these sensitive settings.

Safety - Critical Applications: In applications such as pacemakers and ICDs, any failure in the power supply can be life - threatening for the patient. The ER14250S's robust construction and stable electrochemical reactions ensure a consistent power output. Its hermetically sealed casing protects the internal components from moisture and contaminants in the body, reducing the risk of internal short - circuits or chemical reactions that could lead to power failure. For example, in a pacemaker, if the battery were to malfunction due to a short - circuit caused by moisture ingress, it could disrupt the heart's rhythm regulation, potentially leading to cardiac arrest. The ER14250S's reliable performance helps prevent such critical situations.

Consistent Performance: The battery's stable voltage output is crucial for medical equipment that requires precise electrical signals. In diagnostic devices like ECG monitors, even a slight fluctuation in voltage can affect the accuracy of the readings. The ER14250S maintains a relatively constant voltage during discharge, ensuring that the medical equipment operates within the required specifications. This consistency in performance allows healthcare professionals to make accurate diagnoses based on the data collected by the equipment.

4.2.2 Long - term Stable Power Supply for Implantable Devices

For implantable medical devices, the ability to provide a long - term stable power supply is a key factor.

Extended Battery Life: Implantable devices such as pacemakers and ICDs are designed to last for several years inside the patient's body. The ER14250S's low self - discharge rate means that it can maintain its charge over long periods. For instance, a pacemaker with an ER14250S battery can operate for 5 - 10 years in some cases, depending on the device's power consumption and usage patterns. This long battery life reduces the need for frequent surgical procedures to replace the battery, minimizing the risk and discomfort for the patient.

Stable Discharge Profile: The battery has a stable discharge profile, which is essential for the proper functioning of implantable devices. As the battery discharges, it provides a consistent power output without sudden drops or surges in voltage. In a pacemaker, a stable power supply ensures that the electrical impulses delivered to the heart are of the correct amplitude and frequency, effectively regulating the heart's rhythm. If the battery's discharge profile were unstable, it could lead to irregular pacing, which may not effectively treat the patient's heart condition.

4.2.3 Compatibility with Medical Device Miniaturization Trends

The medical device industry is witnessing a growing trend towards miniaturization, and the ER14250S is well - suited to meet the demands of this trend.

Compact Size for Miniature Devices: The 1/2AA size of the ER14250S is a significant advantage in the context of miniaturized medical equipment. As medical devices become smaller and more portable, there is a need for smaller and more energy - dense power sources. In the case of wearable glucose monitors, the compact size of the ER14250S allows manufacturers to design devices that are unobtrusive and comfortable for patients to wear. These monitors can be as small as a wristwatch, and the battery's size enables it to fit neatly within the device's casing without adding excessive bulk.

High Energy Density for Small - Scale Power Needs: Despite its small size, the ER14250S has a relatively high energy density. This means that it can store a significant amount of energy in a compact form. For small - scale medical sensors that are designed to be implanted or worn on the body, the high energy density of the battery ensures that they can operate for extended periods on a single charge. For example, a miniature sensor used to monitor brain activity in a patient may require a small - sized but high - energy - density battery to power its sensitive electronics. The ER14250S can meet these requirements, providing the necessary power while fitting within the limited space available in the sensor.

5. Comparison with Other Batteries

When considering the use of a battery in a particular application, it is essential to compare its performance with that of other available battery chemistries. The ER14250S, with its unique set of features, stands out in several aspects when compared to common battery types. The following table (Table 8) provides a detailed comparison of the ER14250S with other frequently used batteries in terms of key parameters such as voltage, energy density, self - discharge rate, work temperature range, and rechargeability.

5.1 Voltage Comparison

The ER14250S has a nominal voltage of 3.6V, which is similar to that of common lithium - ion batteries (3.6 - 3.7V). This relatively high voltage is beneficial as it can directly power many electronic devices that are designed to operate within this voltage range or can be used with simple voltage - conversion circuitry. In contrast, Ni - MH batteries have a nominal voltage of 1.2V, and alkaline batteries have 1.5V. For applications that require a higher - voltage power source, multiple Ni - MH or alkaline batteries may need to be connected in series, which can increase the size, weight, and complexity of the power supply system.

5.2 Energy Density

Energy density is a crucial factor as it determines how much energy a battery can store per unit mass. The ER14250S offers a high energy density, typically in the range of 400 - 600 Wh/kg. This is significantly higher than Ni - MH (30 - 80 Wh/kg) and alkaline batteries (50 - 120 Wh/kg). Lithium - ion batteries, although having a medium - high energy density (100 - 260 Wh/kg), are often surpassed by the ER14250S in this regard. In applications where weight is a critical factor, such as in portable medical devices or aerospace components, the high energy density of the ER14250S allows for a more compact and lightweight power source. For example, in a small - scale, long - range environmental monitoring drone, the high - energy - density ER14250S can provide more power in a lighter package compared to Ni - MH or alkaline batteries, enabling longer flight times.

5.3 Self - discharge Rate

As previously discussed, the ER14250S has an extremely low self - discharge rate of less than 1% per month. This is far lower than that of lithium - ion (5 - 10% per month), Ni - MH (10 - 30% per month), and alkaline batteries (2 - 3% per month). In applications where the battery needs to be stored for extended periods before use or in devices with intermittent usage, the low self - discharge rate of the ER14250S ensures that the battery will have sufficient charge when required. In a backup power system for a remote communication tower, the ER14250S can maintain its charge over long periods without frequent recharging or replacement, providing reliable power during power outages.

5.4 Work Temperature Range

The ER14250S's ability to operate in a wide temperature range from - 40°C to + 150°C is a remarkable feature. Lithium - ion batteries have a more limited operating temperature range, typically from - 20°C to + 60 - 80°C, with significant performance degradation outside the 0 - 45°C range. Ni - MH batteries usually operate in the range of - 20°C to + 40 - 60°C, and alkaline batteries in the range of - 20°C to + 50 - 60°C. In high - temperature industrial applications such as oil and gas exploration, down - hole drilling, or in automotive engines where temperatures can reach extreme levels, the ER14250S is the preferred choice. It can continue to function effectively, providing power to sensors and monitoring equipment, while other battery chemistries would fail or experience severe performance issues.

5.5 Rechargeability

The ER14250S is a non - rechargeable battery, which sets it apart from rechargeable lithium - ion and Ni - MH batteries. While rechargeable batteries offer the advantage of multiple uses and reduced long - term cost in applications with high - frequency power consumption, the non - rechargeable nature of the ER14250S can be beneficial in certain scenarios. In applications where simplicity, long - term storage, and low - power consumption are priorities, such as in some medical implant devices or remote - monitoring sensors with infrequent data transmission, the non - rechargeable ER14250S can provide a reliable and maintenance - free power solution. There is no need for complex charging infrastructure or battery management systems, reducing the overall complexity and cost of the device.

6. Future Developments and Challenges

6.1 Potential Improvements in Performance

Enhanced Energy Density: Research efforts are likely to focus on further enhancing the energy density of the ER14250S - like LiSOCl₂ batteries. One approach could be to develop new anode or cathode materials. For example, exploring the use of alternative lithium - alloy anode materials may increase the specific capacity of the anode. Lithium - silicon alloys have a much higher theoretical specific capacity compared to pure lithium, but they face challenges such as significant volume expansion during charging and discharging. If these issues can be overcome, it could lead to a substantial increase in the overall energy density of the battery. In addition, optimizing the cathode material composition, perhaps by adding certain additives to the thionyl chloride - based cathode, could improve its electrochemical reactivity and utilization, thereby increasing the energy density.

Longer Lifespan: Extending the lifespan of the ER14250S is another area of potential improvement. This could involve developing better electrolyte formulations. Current electrolytes in LiSOCl₂ batteries, although effective, may degrade over time due to side - reactions. By developing more stable electrolytes that are less prone to decomposition, the battery's lifespan could be increased. For instance, new electrolyte additives could be introduced to suppress the formation of lithium chloride deposits on the electrodes, which currently contribute to capacity degradation over time. Another aspect could be improving the battery's construction to better withstand the mechanical and chemical stresses during its operation, reducing the likelihood of internal component failure.

6.2 Research and Development Trends

Materials Science Advancements: The field of materials science will play a crucial role in the development of the ER14250S and similar batteries. Scientists are constantly researching new materials with enhanced electrochemical properties. In the case of LiSOCl₂ batteries, this may include the discovery of new cathode materials that can offer higher voltage outputs or better reaction kinetics. For example, the development of nanostructured materials for the cathode could increase the surface area available for the electrochemical reaction, leading to improved performance. Nanoporous carbon materials with tailored pore sizes and surface chemistries could potentially enhance the absorption and utilization of thionyl chloride at the cathode.

Integration with Other Technologies: There is also a trend towards integrating LiSOCl₂ batteries with other emerging technologies. For example, in the Internet of Things (IoT) era, where sensors are becoming increasingly ubiquitous, LiSOCl₂ batteries could be integrated with energy - harvesting technologies such as solar cells or vibration - based energy harvesters. In a remote - monitoring sensor node, a small solar cell could be used to periodically recharge a supercapacitor, which in turn could be used to boost the voltage of the LiSOCl₂ battery during high - power data - transmission periods. This integration could extend the battery's operating time and make the overall system more sustainable.

6.3 Challenges in Mass Production and Cost - effectiveness

High Production Costs: One of the significant challenges facing the ER14250S and LiSOCl₂ batteries in general is the high cost of production. The materials used, especially lithium and thionyl chloride, can be expensive. Lithium is a relatively scarce resource, and its extraction and purification processes are costly. Thionyl chloride also requires careful handling and production techniques. In addition, the manufacturing processes for LiSOCl₂ batteries often involve complex and precise procedures to ensure the quality and performance of the final product. For example, the hermetic sealing of the battery casing, which is crucial for preventing moisture ingress and ensuring long - term stability, requires advanced manufacturing equipment and high - skilled labor. To make these batteries more cost - effective for mass - market applications, manufacturers need to find ways to reduce material costs, perhaps by exploring alternative materials or more efficient extraction methods, and to optimize the production processes to increase efficiency and reduce waste.

Scalability of Production: Scaling up the production of ER14250S batteries to meet the growing demand in various industries is another challenge. As the applications for these batteries expand, especially in the medical, industrial, and aerospace sectors, there is a need to produce them in large quantities. However, maintaining the quality and performance of the batteries during large - scale production can be difficult. Ensuring consistent quality control across a high - volume production line requires sophisticated monitoring and testing equipment. For example, in a high - volume production facility, it is essential to accurately measure and control the composition of the electrolyte and the quality of the electrode materials in each battery unit. Any deviation in these parameters could lead to inconsistent battery performance, reducing the reliability of the product.

6.4 Environmental and Safety Concerns

Environmental Impact: Although LiSOCl₂ batteries like the ER14250S have many advantages, they also pose some environmental concerns. The disposal of these batteries at the end of their life cycle can be an issue. The components of the battery, such as lithium, sulfur, and thionyl chloride, can be harmful to the environment if not properly managed. Lithium, if released into the environment, can accumulate in soil and water bodies, potentially affecting plant growth and aquatic life. Thionyl chloride is a toxic and corrosive substance. To address these concerns, there is a need for the development of efficient battery - recycling technologies. Recycling processes could recover valuable materials such as lithium and reduce the environmental impact of battery disposal. For example, some emerging recycling methods involve using chemical leaching techniques to extract lithium from spent batteries and then purifying it for reuse in new battery production.

Safety Risks: Safety is also a critical concern with LiSOCl₂ batteries. These batteries can generate gas (sulfur dioxide) during discharge, which can increase the internal pressure. If the battery casing is not designed to withstand this pressure, it could lead to leakage or even explosion. In addition, the highly reactive nature of lithium and thionyl chloride means that if the battery is damaged or misused (e.g., short - circuited or over - discharged), it can pose a safety hazard. To mitigate these risks, battery manufacturers are constantly improving the safety features of the battery design. This may include the use of pressure - relief valves in the battery casing to prevent over - pressurization, and the development of more robust separator materials to prevent internal short - circuits.

7. Conclusion

In conclusion, the ER14250S 3.6V high - temperature non - rechargeable lithium battery stands as a remarkable power source with a unique set of characteristics that make it highly valuable in a variety of applications, particularly in the medical field.

Its technical characteristics, such as high - temperature performance up to 150°C, non - rechargeable nature, low self - discharge rate of less than 1% per month, 1/2AA size, and 600mAh capacity, endow it with distinct advantages. The high - temperature tolerance enables its use in extreme - environment applications where other batteries would fail, while the low self - discharge rate ensures long - term charge retention, making it reliable for applications with intermittent use or long - term storage requirements. The compact 1/2AA size allows for easy integration into miniaturized devices, and the 600mAh capacity can meet the power demands of many low - to - medium - power - consuming devices for an extended period.

The chemical principles and internal structure of the LiSOCl₂ battery, of which the ER14250S is a part, play a crucial role in its performance. The electrochemical reactions, with lithium as the anode and thionyl chloride as the cathode - active material and electrolyte solvent, are the basis for its energy - storage and - release mechanism. The internal components, including the anode, cathode, electrolyte, separator, and casing, work in harmony to ensure stable operation, safety, and long - term performance.

In the medical equipment sector, the ER14250S has found significant applications in implantable medical devices like pacemakers and ICDs, as well as portable medical monitoring devices such as wearable glucose monitors and portable ECG monitors. Its reliability in sensitive medical environments, long - term stable power supply for implantable devices, and compatibility with medical device miniaturization trends make it an ideal power source. It ensures the proper functioning of these life - saving and health - monitoring devices, contributing to better patient care and medical diagnosis.

When compared to other batteries, the ER14250S outperforms in several aspects. It has a relatively high voltage, high energy density, extremely low self - discharge rate, and a wide work temperature range. While it is non - rechargeable, this feature can be an advantage in certain applications where simplicity and long - term storage are prioritized.

Looking ahead, there is great potential for the ER14250S in terms of future developments. Improvements in performance, such as enhanced energy density and longer lifespan, are on the horizon through research in materials science and battery design. Integration with other emerging technologies also holds promise for expanding its application scope. However, challenges in mass production, cost - effectiveness, environmental impact, and safety need to be addressed. Overcoming these challenges will be crucial for the widespread adoption and further development of the ER14250S in various industries. Overall, the ER14250S is a significant battery technology with a bright future, especially in meeting the power - supply needs of high - tech and specialized applications.