High temperature battery and Low Temperature Lithium Batteries: Revolutionizing Performance in Extreme Conditions

High temperature battery and Low Temperature Lithium Batteries: Revolutionizing Performance in Extreme Conditions

Introduction

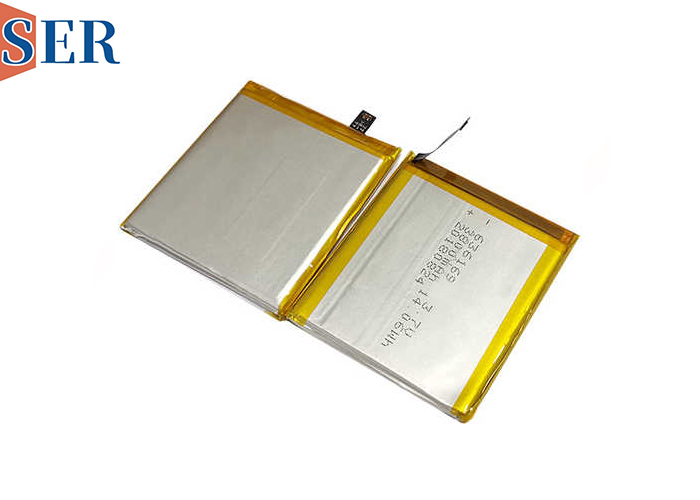

In the realm of electrochemical power sources, lithium batteries have emerged as a dominant force due to their high energy density, long cycle life, and low self-discharge rates. However, conventional lithium batteries often face significant performance limitations when operating in extreme temperature conditions. To address this critical gap, high temperature battery and low temperature lithium batteries have been specifically engineered to excel in both scorching heat and freezing cold. This article delves into the technological advancements, design principles, material formulations, manufacturing processes, and performance characteristics of these specialized batteries.

Technical Background

Conventional lithium batteries exhibit inherent temperature-related vulnerabilities. At high temperatures, they risk thermal runaway, capacity fading, and reduced cycle life, while at low temperatures, their discharge efficiency plummets due to sluggish lithium-ion diffusion and increased internal resistance. High temperature battery and low temperature lithium batteries are developed to overcome these challenges through:

Innovative Design Concepts:

High-Temperature Resistance: Utilizing heat-resistant materials and optimized electrode structures to prevent thermal runaway.

Low-Temperature Adaptability: Employing advanced electrolytes and electrode materials to enhance ionic conductivity in cold environments.

Advanced Material Formulations:

Electrolyte Systems: Tailored blends of solvents and additives to maintain liquidity and conductivity across temperature extremes.

Electrode Materials: Selection of active materials with stable crystal structures and high electrochemical activity at both high and low temperatures.

Rigorous Manufacturing Processes:

Precision control over coating thickness, compaction density, and assembly alignment to ensure uniform performance.

Stringent environmental controls during production to minimize contamination and moisture ingress.

Design Philosophy and Material Formulations

The design of high and low temperature lithium batteries revolves around three core principles: thermal stability, ionic conductivity, and electrochemical reversibility.

Electrolyte Formulation:

Vinylene carbonate (VC): Enhances SEI film formation for improved cycle stability.

Fluoroethylene carbonate (FEC): Boosts low-temperature performance by reducing lithium plating.

Lithium tetrafluoroborate (LiBF₄) and lithium difluorophosphate (LiPO₂F₂): Improve high-temperature stability and electrochemical window.

Solvent Blends: A typical high-performance electrolyte combines ethylene carbonate (EC), ethyl methyl carbonate (EMC), and ethyl propionate (EP) in a 20:30:50 volume ratio.

Additives:

Electrode Materials:

Cathodes: Lithium iron phosphate (LFP) or nickel-cobalt-manganese (NCM) oxides are preferred for their thermal and structural stability.

Anodes: Artificial graphite is commonly used due to its balanced capacity and cycle performance.

Manufacturing Processes

The production of high and low temperature lithium batteries involves 13 critical steps, each requiring precise control to ensure optimal performance:

Electrode Preparation:

Slurry Mixing: Conductive agents, binders (e.g., PVDF), and active materials are blended under vacuum to ensure homogeneity.

Coating: Slurries are applied to aluminum (cathode) or copper (anode) foils using precision coaters, with thickness controlled to ±2μm.

Cell Assembly:

Calendering: Electrodes are compacted to enhance energy density and reduce porosity.

Slitting: Electrodes are cut into strips with controlled burr levels to prevent short circuits.

Winding/Stacking: Electrodes and separators are combined into jelly rolls or stacks with precise alignment.

Final Processes:

Drying: Electrodes and cells undergo vacuum drying to remove residual moisture.

Electrolyte Filling: Cells are flooded with electrolytes in dry rooms (dew point ≤-40℃).

Formation: Initial charge-discharge cycles are performed to activate the electrodes and form stable SEI layers.

Performance Characteristics

High and low temperature lithium batteries exhibit exceptional performance across a wide temperature range:

High-Temperature Performance:

Maintains >90% capacity after 48 hours at full charge.

Thickness swelling <5%.

Volume change ≤0.5% after 24 hours.

No swelling, fire, or explosion under full charge.

70℃ Storage:

85℃ Operation:

Low-Temperature Performance:

Retains >50% of rated capacity.

90% of rated capacity for standard cells.

Special high-rate cells achieve >70% capacity at 1C.

98% of initial capacity at 0.2C rate.

-20℃ Discharge:

-40℃ Discharge:

-50℃ Operation:

Cycle Life and Safety:

Passes nail penetration, overcharge, and short-circuit tests.

Complies with UL/CE/UN safety standards.

Cycle Stability: Exceeds 400 cycles, with high-end products reaching 2000 cycles.

Self-Discharge: <3% per month at 25℃.

Safety Features:

Technical Bottlenecks and Solutions

Despite significant advancements, several challenges remain in the development of high and low temperature lithium batteries:

Low-Temperature Challenges:

Optimized electrolytes: Additives like FEC suppress lithium plating.

Nanostructured electrodes: Enhanced surface area improves ionic conductivity.

Lithium Plating: Slow lithium-ion diffusion at low temperatures leads to metal lithium deposition on anodes.

SEI Film Thickening: Increased impedance due to repeated SEI layer formation during cycling.

Solutions:

High-Temperature Challenges:

Heat-resistant separators: Prevent short circuits under thermal stress.

Thermal management systems: Integrated cooling plates or phase-change materials.

Thermal Runaway: Exothermic reactions at high temperatures risk fire and explosion.

Capacity Fading: Accelerated degradation of electrode materials and electrolytes.

Solutions:

Conclusion and Future Prospects

High temperature battery and low temperature lithium batteries represent a breakthrough in electrochemical energy storage, enabling reliable operation in harsh environments. Their applications span from electric vehicles in arctic regions to industrial equipment in deserts. Ongoing research focuses on:

Next-generation electrolytes: Solid-state or hybrid electrolytes for enhanced safety.

Silicon-based anodes: Higher capacity and improved low-temperature performance.

Smart battery management systems (BMS): Adaptive algorithms for temperature regulation and cycle optimization.

As global demand for energy storage solutions grows, high and low temperature lithium batteries will play a pivotal role in powering a sustainable future, where performance knows no bounds.