Mining While Drilling (MWD) Measurement Device, and What Type of Battery is Used in Mining MWD Measurement Devices

What is a Mining While Drilling (MWD) Measurement Device, and What Type of Battery is Used in Mining MWD Measurement Devices?

I. What is a Mining While Drilling (MWD) Measurement Device?

A Mining While Drilling (MWD) measurement device is a type of measurement equipment used in mining shafts or drilling operations. It is typically employed to measure the properties of underground ore deposits, geological features, rock layer thicknesses, ore grades, and other relevant information.

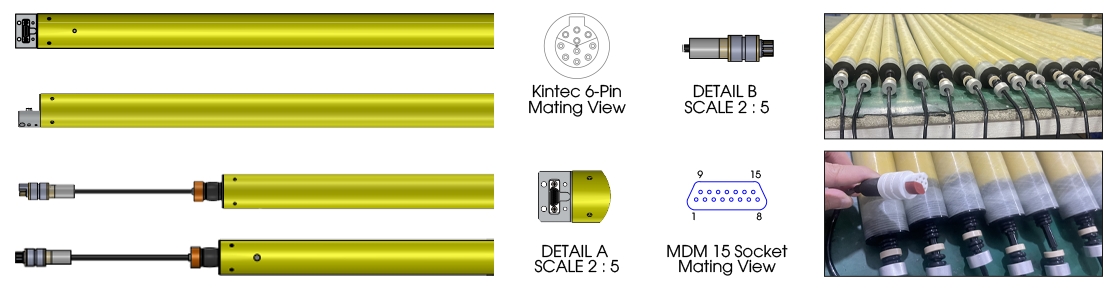

The MWD measurement device is generally installed at the lower part of the drill pipe or drilling tube and lowered into the wellbore or shaft for measurement. It can capture physical data of the wellbore, such as temperature, pressure, flow rate, rock density, etc., and convert these data into readable information through sensors and instruments.

The MWD measurement device usually includes measurement sensors, a data acquisition system, and data analysis software. The measurement sensors can be selected based on requirements, such as pressure sensors, temperature sensors, flow meters, etc. The data acquisition system is responsible for receiving data from the sensors and transmitting it to the data analysis software for processing and interpretation.

The primary purpose of the MWD measurement device is to provide detailed information about underground ore deposits to assist mining companies in making decisions. It can help determine the size, shape, and distribution of ore deposits, assess the grade and quality of ore, optimize drilling and blasting plans, improve mining efficiency, and provide data support for mine planning and development.

Furthermore, the MWD measurement device can be used for geological exploration and mineral resource assessment. By collecting physical parameters and geological information of underground ore deposits, a better understanding of underground geological structures and deposit properties can be obtained, guiding the development and utilization of mineral resources.

In summary, an MWD measurement device is a measurement equipment used in mining shafts or drilling operations. By measuring the properties and geological characteristics of underground ore deposits, it provides data support for the decision-making and planning of mining companies.

II. What Type of Battery is Used in Mining MWD Measurement Devices?

The choice of battery for mining MWD measurement devices typically depends on factors such as device power consumption, operating time requirements, and environmental conditions. Here are several types of batteries that may be used in mining MWD measurement devices:

LiSOCL₂ Battery - High-Temperature Battery:

This specialized high-temperature LiSOCL₂ battery for downhole instruments in directional drilling of oil and natural gas represents a significant technological advancement in the energy industry. Its extended lifespan, high energy density, and robust safety features make it an ideal solution for meeting the complex demands of downhole instruments. By addressing long-standing challenges related to power supply, this high-temperature battery paves the way for more efficient, reliable, and sustainable drilling operations.Lithium Polymer Battery (LiPo battery):

Lithium polymer batteries are also a common battery choice, featuring high energy density and a thinner form factor. They are suitable for devices requiring a thinner design but may slightly lag in lifespan compared to lithium-ion batteries.Lithium-Ion Battery (Li-ion battery):

Lithium-ion batteries are a common battery type known for their high energy density, long lifespan, and low self-discharge rate. This makes them the preferred power source for many portable electronic devices, including mining MWD measurement devices.

The specific choice of battery type depends on factors such as the device's power consumption requirements, volume constraints, weight requirements, and operating time requirements. Additionally, mining MWD measurement devices may need to consider environmental factors, such as temperature, humidity, and explosion-proof requirements.

It is worth noting that the selection and use of batteries should follow relevant safety regulations and recommendations to ensure device reliability and safety. For specific mining MWD measurement devices, it is recommended to refer to the device manufacturer's specifications and instructions to determine the suitable battery type and usage method.