Ultra-thin Non-magnetic Lithium Polymer Battery LP603443 and LP404398 for Active RFID Lithium Batteries

Ultra-thin Non-magnetic Lithium polymer Battery LP603443 and LP404398 for Active RFID Lithium Batteries

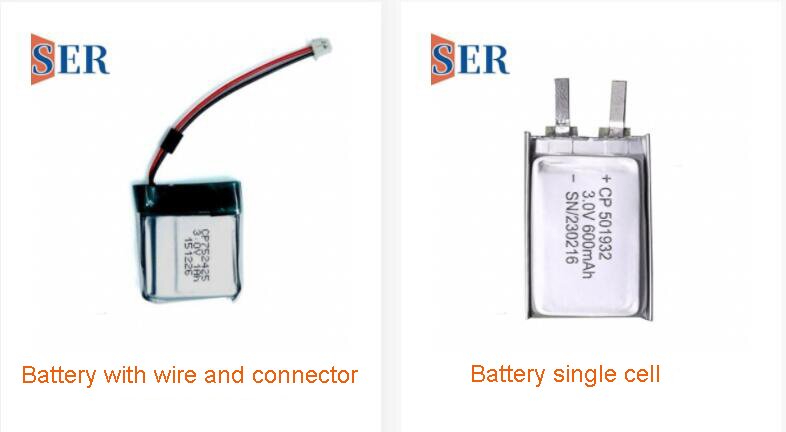

SER Battery has successfully developed and mass-produced completely non-magnetic lithium-polymer batteries through the use of non-magnetic materials, production equipment, and processes. These batteries are specifically designed for use in equipment sensitive to magnetism, such as magnetometers, medical devices, and equipment used in MRI rooms. Below is a detailed introduction to these innovative batteries, including their characteristics, applications, and the technological breakthroughs achieved during their development.

1. Overview of Non-magnetic Lithium-polymer Batteries

In recent years, with the rapid development of various electronic devices, there has been an increasing demand for batteries in the market. Among them, lithium-polymer batteries, due to their high energy density, long cycle life, and customizable shape, have become a popular choice. However, in some specific application scenarios, such as magnetic measurement, medical imaging, and aviation, the use of magnetic materials is strictly prohibited, which poses a significant challenge to the design and production of lithium-polymer batteries.

To meet this challenge, SER Battery has invested significant resources in research and development, ultimately successfully developing a series of completely non-magnetic lithium-polymer batteries. These batteries are produced using non-magnetic materials and specialized production equipment and processes to ensure that they do not generate any magnetic fields during use, thereby satisfying the requirements of applications sensitive to magnetism.

2. Introduction to LP603443 and LP404398 Batteries

LP603443 and LP404398 are two representative products of SER Battery's non-magnetic lithium-polymer battery series. These batteries not only maintain the excellent electrical performance of traditional lithium-polymer batteries but also possess unique non-magnetic characteristics, making them ideal for use in various applications sensitive to magnetism.

2.1 LP603443 Battery

Dimensions and Specifications: The LP603443 battery has a thickness of 3.4mm, a width of 44mm, and a length of 60mm, making it an ultra-thin battery with a compact size. It has a nominal voltage of 3.7V and a nominal capacity ranging from 40mAh to 300mAh, depending on customer needs.

Application Scenarios: Due to its ultra-thin design and non-magnetic properties, the LP603443 battery is widely used in RFID tags, smart cards, wearable devices, and other electronic products that require a small footprint and low magnetic interference.

Advantages: The LP603443 battery offers high energy density, long cycle life, and excellent discharge performance. In addition, its non-magnetic characteristics ensure that it does not interfere with the operation of other electronic devices or medical equipment in sensitive environments.

2.2 LP404398 Battery

Dimensions and Specifications: The LP404398 battery has a thickness of 3.9mm, a width of 43mm, and a length of 40mm, providing a compact and lightweight solution. It has a nominal voltage of 3.7V and a nominal capacity ranging from 20mAh to 200mAh, tailored to meet the needs of various applications.

Application Scenarios: The LP404398 battery is primarily used in RFID tags, smart labels, and other low-power electronic devices. Its non-magnetic properties make it particularly suitable for use in environments where magnetic interference is unacceptable, such as MRI rooms and other medical imaging facilities.

Advantages: The LP404398 battery combines high energy density, long cycle life, and stable discharge performance. Its non-magnetic characteristics ensure that it does not interfere with the sensitive electronic equipment in its operating environment, providing a reliable power solution.

3. Technological Breakthroughs in the Development of Non-magnetic Lithium-polymer Batteries

The development of non-magnetic lithium-polymer batteries by SER Battery involves multiple technological breakthroughs, including material selection, production equipment, and process optimization.

3.1 Material Selection

Electrolyte Materials: Traditional lithium-polymer batteries use electrolytes containing lithium ions and organic solvents. However, some organic solvents may exhibit magnetic properties, which are unacceptable for non-magnetic lithium-polymer batteries. Therefore, SER Battery has developed special electrolytes that do not contain any magnetic materials to ensure the non-magnetic properties of the battery.

Electrode Materials: The electrodes of lithium-polymer batteries are mainly composed of lithium cobalt oxide, lithium nickel cobalt manganese oxide, and other lithium-containing compounds. To ensure the non-magnetic properties of the battery, SER Battery carefully selects electrode materials and avoids using any magnetic materials during the production process.

Packaging Materials: The packaging materials of lithium-polymer batteries are also crucial. SER Battery uses non-magnetic packaging materials such as aluminum-plastic composite films and special adhesives to ensure that the entire battery assembly does not generate any magnetic fields.

3.2 Production Equipment

The production of non-magnetic lithium-polymer batteries requires specialized production equipment to ensure that the battery does not become magnetic during the production process.

Magnetic Field Control Equipment: SER Battery has equipped its production lines with magnetic field control equipment to monitor and control the magnetic field intensity in the production environment. This ensures that the battery does not come into contact with any magnetic materials during the production process, thereby maintaining its non-magnetic properties.

Automated Production Lines: To improve production efficiency and product quality, SER Battery has introduced automated production lines for non-magnetic lithium-polymer batteries. These automated production lines use precision machinery and sensors to ensure the accuracy and stability of the production process.

3.3 Process Optimization

In addition to material selection and production equipment, process optimization is also crucial for the production of non-magnetic lithium-polymer batteries.

Strict Quality Control: SER Battery has established a strict quality control system to monitor every step of the production process. This includes raw material inspection, production process monitoring, and finished product testing to ensure that each battery meets the requirements for non-magnetic properties and electrical performance.

Environmental Control: The production environment of non-magnetic lithium-polymer batteries is also crucial. SER Battery has established a dust-free and static-free production workshop to ensure that the production environment is clean and stable. This helps to reduce the risk of contamination and damage during the production process and improves the reliability of the battery.

4. Applications of Non-magnetic Lithium-polymer Batteries

Due to their non-magnetic properties and excellent electrical performance, non-magnetic lithium-polymer batteries have a wide range of applications, including but not limited to the following:

4.1 RFID Tags and Smart Labels

RFID tags and smart labels are widely used in logistics, retail, and other industries for inventory management and product tracking. Non-magnetic lithium-polymer batteries provide reliable power support for these devices, enabling them to operate stably in various environments.

4.2 Medical Equipment

In the medical field, many devices are sensitive to magnetic interference, such as magnetometers, MRI machines, and other imaging equipment. Non-magnetic lithium-polymer batteries can be used as power sources for these devices to ensure their accurate and stable operation.

4.3 Aviation and Aerospace

In the aviation and aerospace fields, magnetic interference may have a significant impact on the operation of aircraft and spacecraft. Therefore, non-magnetic lithium-polymer batteries are widely used in these fields to provide reliable power support for various electronic devices.

4.4 Other Applications

In addition to the above applications, non-magnetic lithium-polymer batteries can also be used in various other scenarios, such as wearable devices, smart home appliances, and other electronic products that require small footprints and low magnetic interference.

5. Comparison with Traditional Lithium-polymer Batteries

Compared with traditional lithium-polymer batteries, non-magnetic lithium-polymer batteries have the following differences and advantages:

5.1 Material Differences

As mentioned earlier, non-magnetic lithium-polymer batteries use special materials that do not contain any magnetic materials to ensure their non-magnetic properties. This is the most significant difference between them and traditional lithium-polymer batteries.

5.2 Production Process Differences

The production process of non-magnetic lithium-polymer batteries is more complex and requires stricter quality control and environmental control. This ensures that the battery does not become magnetic during the production process and maintains its non-magnetic properties.

5.3 Application Advantages

Due to their non-magnetic properties, non-magnetic lithium-polymer batteries have broader application scenarios. They can be used in environments where traditional lithium-polymer batteries cannot be used due to magnetic interference issues. This greatly expands the application range of lithium-polymer batteries and provides more choices for users.

6. Future Development Trends of Non-magnetic Lithium-polymer Batteries

With the continuous development of various electronic devices and the increasing demand for batteries, non-magnetic lithium-polymer batteries will have broader application prospects in the future. The following are some future development trends of non-magnetic lithium-polymer batteries:

6.1 Higher Energy Density

With the continuous improvement of battery technology, non-magnetic lithium-polymer batteries will have higher energy density in the future.